OEM Materials provides Just-In-Time (JIT) Packaging Replenishment Services designed for fast-moving manufacturing, assembly lines, warehouses, and operations that rely on precision timing. Instead of storing large amounts of packaging or production materials, JIT ensures you receive exactly what you need, delivered precisely when your process requires it.

Just-In-Time replenishment is a supply chain system where OEM Materials delivers packaging and production materials at the exact moment you need them, no sooner and no later. Instead of keeping shelves full of unused stock, materials arrive based on your real usage, production schedule, and demand patterns. JIT reduces carrying costs, improves space efficiency, and keeps your operation agile while preventing downtime caused by missing supplies.

Below is a detailed overview of our JIT capabilities, engineered to support high-volume manufacturing, lean production systems, and fast-paced distribution environments.

We deliver packaging and facility supplies in line with your production workflow. We provide packaging daily, weekly, shift-based, or timed to specific job runs. This ensures your team always has what they need without storing extra material.

OEM Materials analyzes your real-time consumption and delivers materials only when demand requires it. This keeps your workflow smooth, reduces waste, and prevents buildup of slow-moving items.

We forecast upcoming requirements using your job schedules, seasonal trends, and demand spikes. Whether production ramps up or slows down, your replenishment adjusts automatically.

JIT reduces unnecessary storage, freeing up floor space for production instead of pallets of inventory. This supports lean manufacturing, 5S environments, and continuous improvement programs.

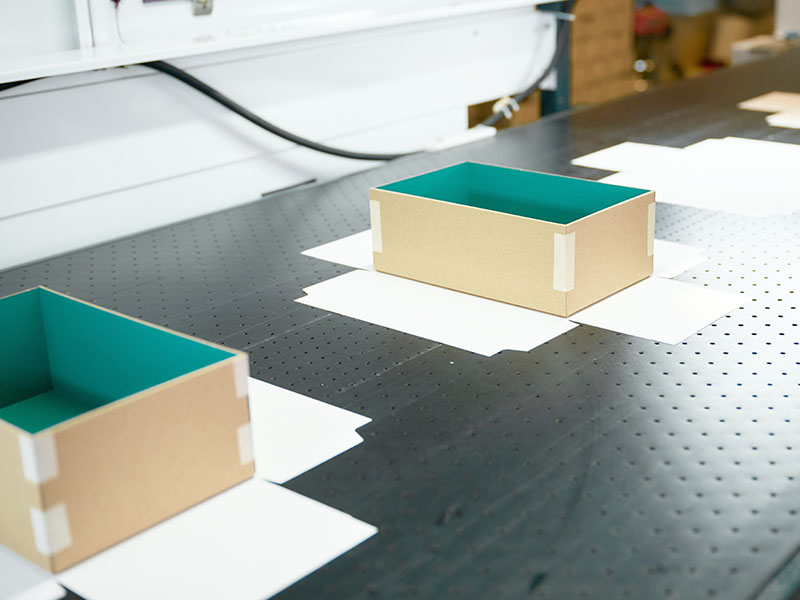

We deliver and stage your materials at the exact point of use, including pack stations, assembly cells, or racking lanes. Your operators stay focused on production rather than on retrieving supplies.

For companies operating multiple plants or warehouses, we coordinate replenishment schedules across all locations. You get consistent timing, less downtime, and standardized stocking practices throughout your network.

JIT reduces excess ordering, eliminates “just in case” storage, and lowers your overall inventory investment. Many facilities see reduced waste, fewer emergencies, and smoother long-term budgets.

Your replenishment schedule is tailored to your process, usage patterns, and work areas. Whether you need hourly drop-offs, shift-based restocking, or weekly scheduled deliveries. We build the program around your operation.

You receive only what you need, when you need it, reducing waste, storage costs, and clutter on the floor.

Materials arrive at the correct moment so your lines keep moving without delays or stockouts.

With less stored inventory, you gain room for production, staging, or process improvements.

JIT helps reduce tied-up cash, eliminate obsolete items, and smooth purchasing cycles.

Every delivery follows a strict schedule based on your workflow. So, no surprises, no guesswork.

OEM Materials supports lean-driven facilities that need precise replenishment timing.

Timed deliveries for strict build schedules, export packaging, and sensitive components.

Cleanroom consumables, packaging, and production materials delivered right when needed.

ESD materials, cleanroom bags, foam, and packaging stocked at precise intervals.

Corrugated, foam, poly, labels, pallets, and assembly consumables delivered based on takt time.

Timed replenishment for heavy-duty production lines and high-speed assembly workflows.

Scheduled deliveries for shipping supplies, labels, packaging film, and order fulfillment materials.

OEM Materials supports facilities across the United States with regional stocking, reliable logistics, and tailored replenishment programs.

We provide JIT delivery for facilities across the U.S., ensuring stable supply regardless of location.

Strategically placed warehouses enable faster deliveries and tighter replenishment windows.

We coordinate timing and supply flow across all your facilities for consistent JIT performance.

Nearby customers receive accelerated replenishment cycles and rapid resupply options.

OEM Materials builds replenishment programs that match your production rhythm and operating needs, helping you reduce cost, eliminate delays, and keep your workflow moving smoothly.

JIT replenishment means you get the supplies you need exactly when your operation needs them, not weeks early and never too late. OEM Materials tracks your usage and production schedule, then delivers materials at the right moment to keep your workflow moving. This helps reduce storage costs, prevent overstocking, and keep your facility running lean and efficient.

Each day or shift, your team uses materials normally while we track consumption and timing. Based on your replenishment schedule, we deliver supplies directly to your pack stations, warehouse areas, or production cells. You don’t have to place constant orders or chase low stock. Materials simply arrive when your operation needs them, keeping things smooth and predictable.

We replenish nearly all packaging and production materials, including corrugated boxes, stretch film, tape, labels, foam, poly bags, ESD products, PPE, and warehouse supplies. If your team uses it regularly, we can time its delivery for JIT replenishment. Most customers start with their most-used items, then expand once they see how much time and space JIT saves.

JIT reduces inventory by cutting out excess “just in case” stock. Instead of keeping weeks or months of supplies on the floor, you receive smaller amounts more often, matched to your actual usage. This frees up space, lowers carrying costs, prevents over-ordering, and helps avoid expired, damaged, or forgotten materials sitting in storage.

No. JIT is designed to prevent stockouts by delivering materials at the exact right time. We monitor usage, staging levels, lead times, and your production plans. Deliveries are scheduled before you run low, so you never reach empty shelves. This approach creates a smooth, predictable workflow that helps you avoid emergencies and downtime.

We look at your daily or weekly usage, production schedule, shift requirements, job volume, and lead times. Based on that data, we build a replenishment schedule that matches your real needs. Deliveries can be timed by day, shift, job, or even takt time depending on your process. As conditions change, we adjust timing to keep everything in sync.

Yes. JIT is ideal for environments where production changes often. We analyze your real usage and adjust delivery timing as orders shift, volumes rise, or priorities change. JIT programs are flexible by design and update as your workflow evolves. Whether production speeds up or slows down, your replenishment adapts automatically.

Traditional ordering leaves you with too much stock or not enough. JIT eliminates guesswork by delivering supplies at the moment you need them. This reduces storage space, keeps materials fresh, lowers cost, improves organization, and helps prevent delays caused by missing supplies. It also frees your team from constant ordering and inventory tracking.

Yes. We can manage JIT replenishment for one location or for multiple plants, warehouses, or distribution centers across the country. We coordinate schedules, usage tracking, and deliveries for every site so each facility stays stocked without storing too much. Multi-site customers benefit from consistent timing, lower costs, and fewer disruptions.

When supplies arrive exactly when needed, your team doesn’t waste time searching for materials, opening emergency orders, or reorganizing cluttered storage areas. Pack stations stay stocked, assembly lines keep moving, and supervisors deal with fewer supply issues. This creates a smoother, more predictable workflow that boosts overall productivity.

You can receive regular reports that show usage patterns, delivery timing, cost trends, and adjustments needed for future replenishment. These reports help you understand how much you’re using, plan upcoming budgets, spot waste, and improve your process. They make your supply chain easier to manage and more transparent.

Yes. JIT helps reduce carrying costs, eliminate over-ordering, limit obsolete inventory, and lower emergency shipping expenses. You buy what you need when you need it—no extra stock sitting on shelves. Over time, most facilities see better cost control, improved forecasting, and fewer surprises in their supply budgets.

Absolutely. Smaller operations benefit from JIT because they often have limited storage space and need steady supply flow. You don’t have to be a huge plant to see savings and efficiency improvements. If you use certain supplies regularly, JIT can streamline your process, reduce clutter, and help you avoid running out during busy periods.

Setup time depends on how many items you want included and how detailed your schedule needs to be. Most programs start quickly. We review your usage, walk your facility, build a replenishment schedule, and set up staging points. Once we finalize timing, JIT deliveries begin and then adjust over time as we learn your flow.

To get started, we usually need your frequently used items, recent usage numbers, production timing, storage layout, preferred brands, and any special requirements. A quick walkthrough of your facility helps us understand your workflow. From there, we design a schedule and delivery plan that fits how your team works each day.