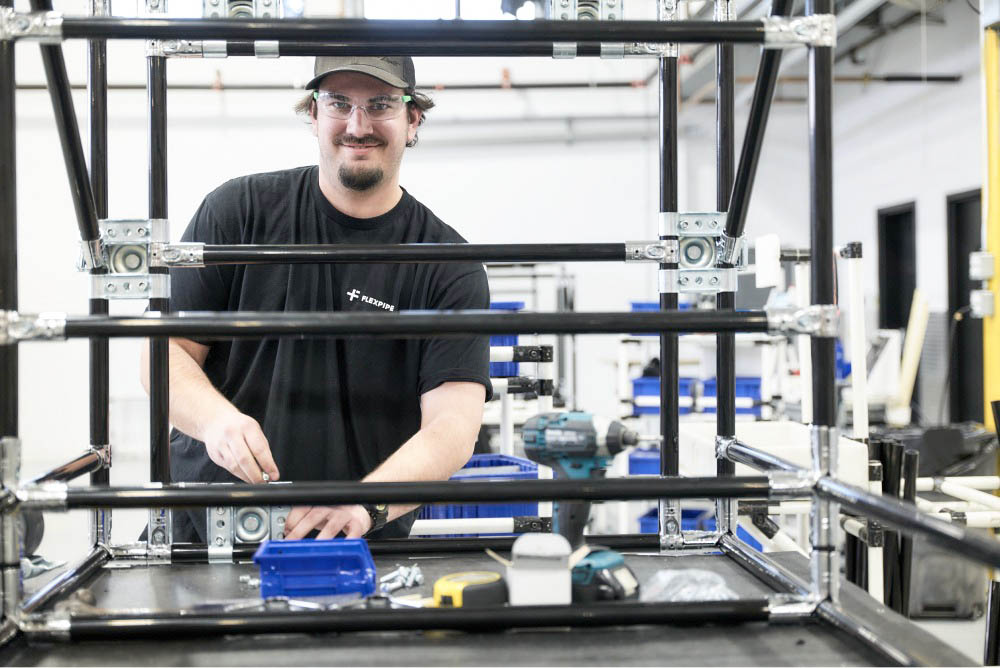

OEM Materials provides turnkey Flexpipe Assembly Services designed for manufacturers, warehouses, assembly operations, and distribution facilities that need flexible, ergonomic, and highly efficient material-handling structures. We design, build, and deliver custom Flexpipe systems that support lean workflows, improve organization, and adapt quickly as your production needs evolve. From workstations to flow racks and mobile cells, every structure is assembled in-house for accuracy, durability, and immediate use.

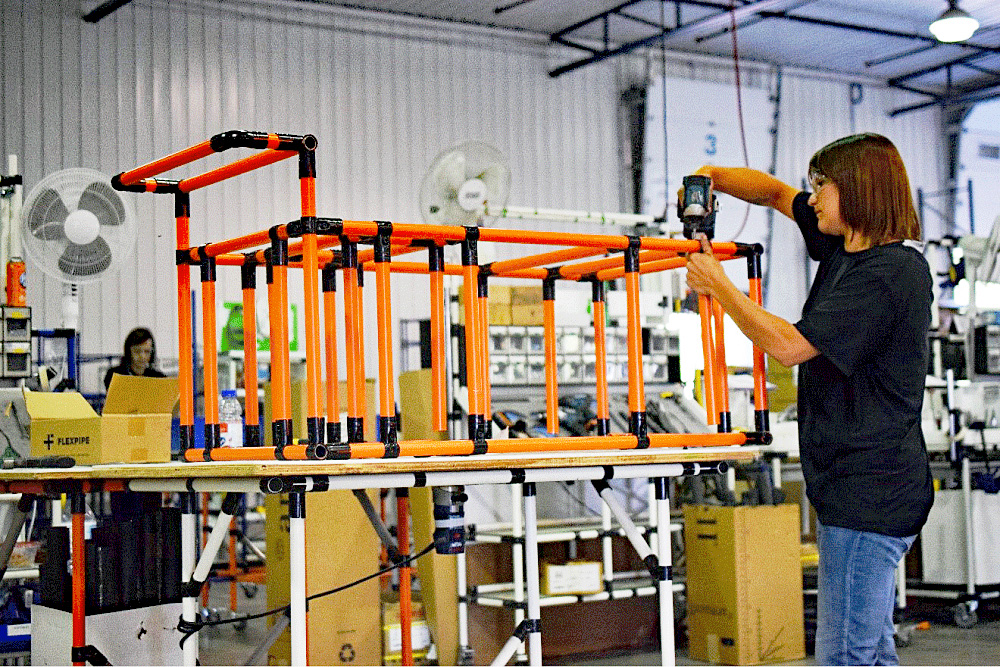

Flexpipe is a modular building system that uses steel pipes, joints, casters, and accessories to create custom structures that improve workflow, increase efficiency, and support 5S principles. OEM Materials engineers and assembles these structures based on your process, space, and handling requirements. Unlike fixed metal racks or pre-built stations, Flexpipe systems are fully customizable, lightweight, reconfigurable, and built to grow with your operation.

Below is a detailed overview of our Flexpipe capabilities, designed to support lean production systems, assembly lines, kitting operations, warehouses, and fast-changing manufacturing environments.

We design and assemble ergonomic workstations tailored to your operators’ tasks, tools, and workflow. Each workstation is built for comfort, reach efficiency, and repeatable daily performance. Whether you need static benches, seated stations, or height-adjustable work areas, we build structures that support productivity and reduce strain.

Our team builds custom Flexpipe flow racks and FIFO (First-In, First-Out) lanes to improve material movement and ensure proper stock rotation. These structures integrate smoothly with kitting, assembly, and production lines, helping eliminate bottlenecks and maintain consistent throughput.

We design carts and mobile handling systems that move tools, components, and assemblies efficiently between work areas. Casters, shelves, hooks, and modular accessories allow for smooth transport and improved organization. Mobility gives your team greater flexibility across changing production needs.

We develop Flexpipe systems that organize, position, and present parts at exactly the right height and angle for your operators. This reduces motion waste, improves picking accuracy, and speeds up assembly. Kitting racks are ideal for build-to-order and high-mix production environments.

OEM Materials builds Flexpipe structures that support 5S, visual control, and workplace standardization. Shadow boards, labeling systems, tool stations, and custom storage structures keep supplies visible, accessible, and consistently placed, reducing time lost searching for tools or parts.

All Flexpipe structures are assembled in our warehouse for quality, safety, and accuracy. When delivered, they arrive ready to put into service immediately, no onsite construction, no missing components, and no delays. This reduces installation time and ensures the structure works perfectly from day one.

Flexpipe’s modular design allows fast modifications as your workflow evolves. We can reconfigure, expand, or adjust your structures without replacing the entire system. This makes Flexpipe ideal for continuous improvement initiatives, seasonal changes, and growing production demand.

Every structure is designed around your process to reduce wasted motion, shorten travel distance, and support smoother, faster production.

We build Flexpipe systems that reduce strain, improve reach zones, and create comfortable, repeatable work conditions that support operator safety and performance.

Flexpipe is a core tool for supporting lean initiatives, enabling teams to implement FIFO, 5S, visual control, and continuous improvement across production.

We handle everything, from design to assembly to delivery, so you receive a complete, ready-to-use structure without needing in-house construction or special tools.

Flexpipe structures are built to withstand daily industrial use while remaining easy to adjust or expand. This creates long-term value and operational flexibility.

OEM Materials supports a wide range of industries where modular structures and lean processes are essential.

Custom workstations, carts, and racks for precision assemblies, kitting, and sensitive components.

Ergonomic and clean workflow structures that improve organization and accuracy in assembly and inspection processes.

ESD-safe Flexpipe stations and racks for delicate, high-value components.

Modular systems that support build-to-order lines, multi-stage assembly, and efficient parts presentation.

Durable, mobile handling systems for heavy components and fast-paced production environments.

Flow racks, pick stations, and mobile carts that support order fulfillment, restocking, and high-density storage.

OEM Materials supports facilities across the United States with full design, assembly, and delivery of Flexpipe systems.

We supply and assemble Flexpipe structures for facilities nationwide, large and small.

With strategic production and assembly locations, we build and deliver Flexpipe systems quickly and reliably across the U.S.

We support companies with multiple plants or distribution centers, ensuring consistency and standardization across locations.

Regional customers benefit from quick turnaround times, rapid delivery, and responsive support based on production schedules.

With OEM Materials designing and assembling your Flexpipe structures, you gain a leaner, more organized, and more productive operation built around your workflow.

Flexpipe is a modular pipe-and-joint construction system used to build custom workstations, carts, racks, and other material-handling structures. Unlike fixed steel equipment, Flexpipe is lightweight, fully customizable, and easy to adjust as your workflow changes. It improves ergonomics, supports 5S, enhances material flow, and allows your production floor to adapt quickly without expensive redesigns or downtime.

OEM Materials can build nearly any structure your operation needs, including workstations, flow racks, FIFO lanes, mobile carts, kitting racks, inspection tables, shadow boards, tool stations, packing cells, and modular storage solutions. Because Flexpipe is customizable, we can create single-use structures for one workstation or large-scale systems that support entire production lines or multi-stage assembly areas.

We begin by reviewing your workflow, operator requirements, space constraints, and material-handling needs. Then we design a Flexpipe structure tailored to your exact process. Once approved, we assemble the system in our warehouse to ensure quality and accuracy. When delivered to your facility, it arrives fully built and ready to use, eliminating onsite construction, missing parts, or setup delays.

We offer both. You can purchase individual Flexpipe components, including pipes, joints, casters, roller tracks, and accessories, or choose complete pre-assembled structures built by our team. Many customers prefer assembled systems to avoid the time, tools, and training required for in-house builds, while others order components for ongoing improvements or expansions.

Yes. Flexpipe is designed for continuous improvement and can be easily modified without replacing the entire structure. If your workflow changes, new SKUs are added, or ergonomic adjustments are needed, Flexpipe can be expanded, resized, or reconfigured quickly. This makes it ideal for high-mix, fast-changing environments where flexibility is critical for efficiency.

Flexpipe is built from steel pipes with high-strength joints and industrial-grade accessories. The system is designed to withstand daily use in manufacturing, assembly, logistics, and warehouse environments. Even with constant movement, loading, and adjustment, Flexpipe maintains rigidity and long-term performance. It provides the strength of traditional steel structures with the added advantage of modular flexibility.

Flexpipe is used across aerospace, defense, medical devices, automotive, electronics, semiconductor, distribution, warehousing, and OEM manufacturing. Any industry that values efficiency, organization, ergonomics, and lean practices benefits from Flexpipe. It’s especially useful where teams need adaptable structures for kitting, assembly, quality control, and material handling.

Flexpipe allows us to build stations tailored to operator height, reach zones, tool placement, and handling needs. This reduces bending, stretching, lifting, and unnecessary motion, which lowers fatigue and injury risk. Ergonomic improvements also speed up cycle times and create more consistent work output, especially in repetitive or multi-step assembly environments.

Flexpipe flow racks use roller tracks to deliver parts to operators at the right height and angle, improving picking speed and accuracy. FIFO lanes ensure older stock is used first, preventing buildup of outdated materials and supporting lean inventory control. These systems reduce congestion, eliminate bottlenecks, and maintain consistent throughput across production lines.

Absolutely. Flexpipe aligns perfectly with lean principles because it supports visual control, standardized work, efficient material flow, and operator-driven improvements. Structures can be quickly adjusted to support new processes or layout changes. Tools like shadow boards, labeled storage areas, and organized workstations help maintain 5S and improve long-term productivity.

Lead times depend on the complexity of the structure and component availability, but most designs are completed quickly and move into assembly shortly after approval. Because everything is built in-house, we maintain quality and speed throughout the process. Once completed, we deliver the structure ready for immediate use, reducing downtime and accelerating project timelines.

To get started, we typically need details about your workflow, the parts or materials being handled, operator movements, available floor space, ergonomic requirements, and any specific goals such as reducing motion waste or improving organization. Photos or videos of your current process are helpful. With this information, we design a structure that supports your exact operation and delivers measurable efficiency gains.