OEM Materials supports manufacturers, brands, and distribution teams across the United States with packaging solutions designed to reduce damage, control costs, and keep operations moving. We focus on packaging that performs in real shipping environments—not just on paper. Whether you ship pallets, parcels, or mixed loads, we provide stock packaging, custom protection, and replenishment programs that scale with your business.

We serve industries nationwide with custom and stock packaging solutions designed to protect products, improve pack-out, and control shipping costs.

Best for: Manufacturers, processors, distributors

We supply complete food packaging solutions designed for consistent shipping and efficient pack-out. From corrugated boxes and food-grade liners to insulation and load containment, our materials protect product, improve handling, and keep food moving reliably from warehouse to customer nationwide.

Best for: Bottlers, breweries, distributors

Our beverage packaging solutions reduce breakage and improve pallet stability for cans, bottles, and liquid products. We provide heavy-duty shippers, dividers, foam inserts, and palletizing supplies that support safer transport and more efficient fulfillment at scale.

Best for: OEMs, Tier suppliers, aftermarket

We provide automotive packaging that supports repeatable pack-out and smooth production flow. Our solutions include custom foam dunnage, bulk corrugated boxes, partitions, and corrosion protection that keep parts organized, protected, and ready for the line.

Best for: Assemblers, OEMs, distributors

Our electronics packaging protects sensitive components from ESD, shock, and handling damage. We supply anti-static materials, ESD bags, conductive foam, custom inserts, and engineered cushioning to reduce failures, returns, and costly rework during shipping and storage.

Best for: Pharma manufacturers, 3PLs, labs

We supply pharmaceutical packaging that supports safer handling and consistent distribution. Our shippers, insulation, protective materials, and labeling supplies help reduce breakage, improve pack consistency, and support reliable deliveries for regulated products.

Best for: Aerospace manufacturers, MROs, suppliers

Our aerospace packaging solutions protect high-value components through storage and transit. We provide engineered cushioning, heavy-duty shippers, corrosion protection, and stabilization materials designed to reduce damage, delays, and disruptions in critical supply chains.

Best for: Building product manufacturers, suppliers

We supply durable construction packaging that holds up to rough handling and jobsite conditions. Our heavy-duty boxes, pallet protection, wrap, and strapping help reduce damage, rework, and delays from warehouse to jobsite.

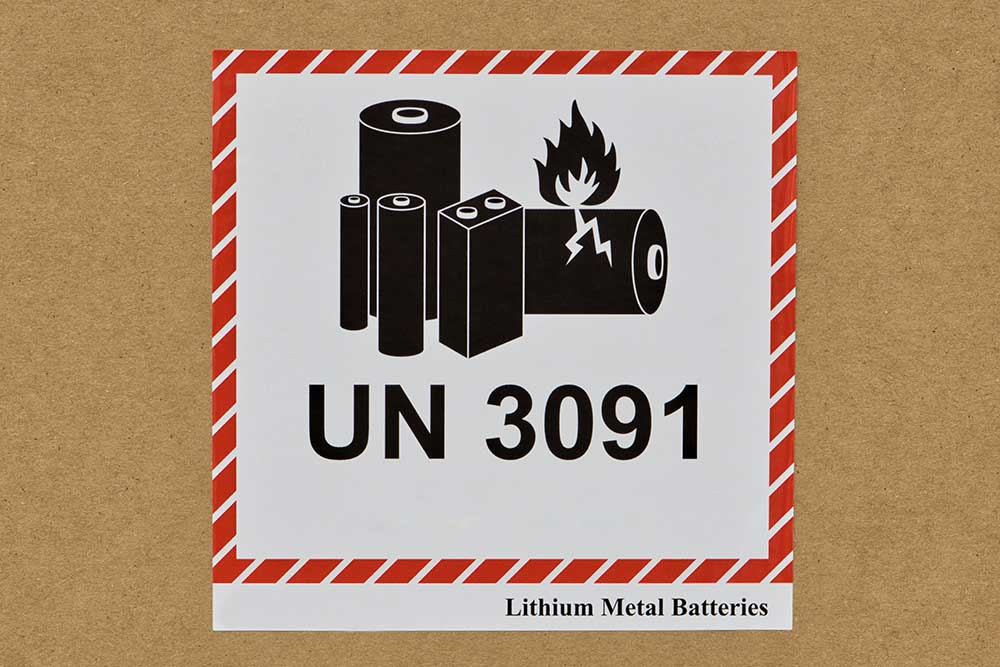

Best for: Chemical, industrial, regulated shippers

We support hazardous shipments with packaging materials that improve safety and consistency. Our offerings include UN-rated boxes (when required), absorbents, liners, containment, and stabilization supplies designed to reduce leaks and transport risk.

Best for: Brands, distributors, retailers

We provide consumer goods packaging that balances protection, speed, and presentation. Our cartons, inserts, void fill, labels, and pack-out materials help reduce damage, streamline fulfillment, and support consistent deliveries at any volume.

Best for: DTC brands, fulfillment centers

Our ecommerce packaging is built for speed, protection, and cost control. We supply mailers, boxes, cushioning, labels, and right-sizing options that reduce damage, improve unboxing, and keep high-volume fulfillment running efficiently.

Best for: Growers, packers, distributors

We supply produce packaging designed for freshness and fast-moving distribution. Our ventilated boxes, liners, pads, and pallet stability materials help reduce bruising, manage moisture, and support cleaner deliveries across the supply chain.

Best for: Furniture manufacturers, distributors

Our furniture packaging protects large and delicate items from dents and scuffs. We supply foam, corrugated pads, edge guards, wrap, and heavy-duty cartons that reduce damage claims and improve load stability during transport.

Best for: Medical OEMs, distributors

We provide medical equipment packaging that protects high-value, sensitive products. Our custom cushioning, durable shippers, overwrap, and stabilization materials reduce handling risk and help ensure equipment arrives ready for use.

Best for: Apparel brands, ecommerce, wholesalers

We supply clothing packaging that ships clean, looks professional, and controls costs. Our mailers, boxes, tissue, inserts, labels, and return-friendly options support faster fulfillment and a better customer experience.

Designed for operations, not just shipping.

Right-sized packaging, engineered protection, and consistent materials help your team pack faster, reduce handling steps, and ship more orders per shift.

Our packaging is built to protect products in real shipping conditions, reducing transit damage, rework, returns, and costly freight claims across your supply chain.

We keep your packaging materials in stock and flowing with reliable replenishment programs that eliminate downtime, shortages, and last-minute sourcing stress.

Our team designs custom foam, corrugated, and hybrid packaging solutions that improve protection, lower costs, and streamline your packing process.

With reliable nationwide delivery, we support multi-location operations and fast-moving supply chains without delays, gaps, or inconsistent service.

Work with packaging specialists who understand materials, shipping environments, and real-world handling, so you get solutions that actually perform.

Stop guessing on packaging. Get expert recommendations based on your product, shipping method, and damage risks. Our team helps you reduce claims, speed pack-out, and control packaging costs.

Packaging problems usually show up as damage, delays, or rising costs, but the root cause is almost always the same: packaging was never designed for how the product actually ships. Our process fixes that. We work with your team to understand your product, your handling environment, and your volume, then build packaging that performs consistently at scale.

We start by understanding what you ship, how it moves, and where damage or inefficiencies occur. Our team reviews product dimensions, weight, fragility, handling steps, shipping methods, and volume patterns to identify risk points. This allows us to recommend packaging that protects product without overpacking or increasing cost.

Based on your operation, we either select proven stock materials or design custom packaging to match your needs. This may include corrugated shippers, foam inserts, partitions, ESD protection, insulation, or load containment. Every recommendation balances protection, speed, and cost so your team can pack efficiently and ship with confidence.

Once packaging is selected, we help refine how it’s used. We evaluate pack-out steps, material usage, and load stability to eliminate wasted motion and inconsistency. The result is standardized packaging that reduces damage, speeds fulfillment, and makes training easier across shifts and locations.

After packaging is in place, we keep it flowing. OEM Materials supports nationwide delivery and replenishment programs that ensure you never run short on critical supplies. Whether you ship from one location or many, we maintain consistent inventory so your operation keeps moving without disruption.

Start with a quick review and get expert recommendations tailored to your product and shipping environment.

OEM Materials serves manufacturers, brands, and distribution teams across the U.S., including food and beverage, automotive, electronics, pharmaceutical, aerospace, construction, hazardous materials, consumer goods, ecommerce, produce, furniture, medical equipment, and apparel. We support parcel and pallet shipping with packaging that reduces damage, speeds pack-out, and stays reliably in stock for day-to-day operations. We help you select packaging materials that match your industry, shipping environment, and throughput targets.

Yes. We design custom protective packaging when stock items are not enough. That can include engineered foam inserts, corrugated partitions, dunnage, and hybrid packs built around your product’s size, weight, and fragility. The goal is simple: reduce transit damage, improve packing speed, and lower total packaging cost by right-sizing and standardizing pack-out. We can support prototypes through production runs, and we document specs so your team can reorder confidently. That keeps procurement and packing teams aligned.

Yes. We review how your product is handled and shipped, then recommend packaging that controls movement, absorbs impact, and improves load stability. Solutions may include stronger corrugated, inserts, cushioning, edge protection, and better pallet containment. When packaging stays consistent, teams typically see fewer damaged deliveries, less rework, and fewer chargebacks or freight claims. We can also recommend pack-out standards and containment methods that improve consistency across every shipment.

The right packaging depends on weight, fragility, and how the item ships. For many fragile or high-value products, custom foam inserts or corrugated partitions paired with the correct shipper provide the most consistent protection. We can also add edge guards, void fill, and pallet stabilization to reduce vibration, drops, and scuffs while keeping pack-out efficient. We can review your current pack-out and recommend changes that improve protection without adding unnecessary material cost. That helps reduce returns and reships.

Yes. We supply ecommerce packaging built for speed and cost control, including shipping boxes, mailers, void fill, tape, and labels. We also help with right-sizing so you use the smallest practical box and the right protection for the product. That can reduce DIM weight costs, improve the unboxing experience, and lower damage and return rates as volume scales. If you ship multiple SKUs, we can help standardize box sizes and inserts to simplify picking, packing, and replenishment. That improves pick-pack accuracy.

Yes. We supply food packaging components such as corrugated boxes, food-grade poly bags and liners, and protective materials used in food shipping and distribution. We focus on packaging that performs in cold chain or ambient conditions and holds up to real handling. Tell us what you ship and how it moves, and we’ll recommend materials that fit your application and workflow. We can also support labeling, load containment, and packaging replenishment so food shipments stay consistent week to week.

Yes. For electronics packaging, we provide ESD and anti-static options such as shielding bags and conductive or dissipative foams, plus custom cushioning and partitions. These materials help protect sensitive components from electrostatic discharge, shock, and vibration during storage and transit. We’ll match the packaging to your handling environment, risk level, and shipping method for consistent results. We can help standardize ESD materials and handling steps so teams pack consistently across shifts and locations.

We support hazardous material shipments with packaging components such as UN-rated boxes when required, absorbents, containment materials, liners, and stabilization supplies. Because hazmat rules vary by product, we work from your shipping requirements to help you select appropriate materials that reduce leak risk and support safer handling and transport. You provide the requirements; we supply compliant packaging materials. We can help you build a repeatable packaging bill of materials so shipments stay consistent and easier to audit.

Yes. OEM Materials supports customers across the United States with reliable delivery for stock packaging and custom solutions. We help single-site and multi-location operations keep consistent materials on hand, so teams avoid last-minute sourcing and downtime. Ask about replenishment programs that keep critical items available on schedule while controlling inventory levels and spend. We can set up recurring deliveries so your locations stay stocked with the same specs and lead times. We support single sites and national footprints.

Yes. We help organizations standardize packaging specs, pack-out steps, and materials across warehouses and plants. Standardization reduces variation between shifts and sites, improves training, and lowers damage caused by inconsistent packing. We can align box styles, inserts, labeling, and pallet containment so every location ships the same way, improving predictability for customers and carriers. We can also create a standard packaging library so new sites can onboard quickly with the same materials and steps.

We supply a wide range of shipping and protective packaging, including corrugated boxes and mailers, foam and cushioning, partitions and dunnage, stretch film, strapping, tape, labels, pallet protection, and specialty materials like ESD and VCI. If you have specific performance requirements—drop protection, vibration control, moisture protection, or corrosion control—we can source, spec, or design the right solution. We can consolidate sourcing and provide consistent specs so you get repeatable performance and simpler purchasing.

Start with a packaging review. Share what you ship, where damage or inefficiency occurs, and how orders move through your operation. We’ll recommend stock supplies or custom packaging, then help you optimize and standardize pack-out for speed and protection. If you need ongoing supply, we can set up replenishment so materials arrive consistently, stay in spec, and support predictable fulfillment. We’ll document packaging specs and reorder points so your team can scale without packaging shortages or surprises.