OEM Materials delivers high-quality industrial supplies, packaging products, and custom protective solutions built for manufacturing, assembly, and distribution. From ESD-safe materials to custom foam inserts, we help electronics manufacturers protect sensitive components and ship with confidence.

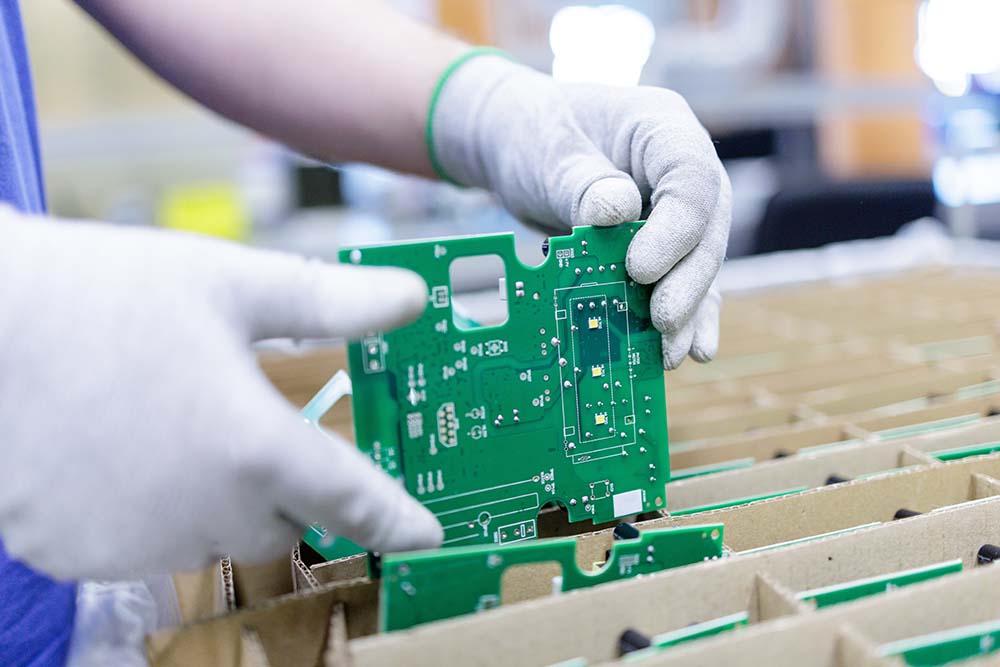

Electronics packaging must protect against more than impact. It must control electrostatic discharge, limit vibration, prevent moisture exposure, and keep parts stable through repeated handling. At OEM Materials, we supply electronics packaging materials designed for real-world shipping and manufacturing environments, not lab conditions. Our customers rely on consistent packaging performance to reduce failures, prevent returns, and protect brand reputation. We support electronics manufacturers, contract assemblers, and distributors across the United States with dependable packaging supplies that scale with volume and production demands.

ESD-safe packaging is critical for protecting electronic components from electrostatic discharge during handling and shipping. We supply anti-static, static-dissipative, and shielding bags in multiple sizes and formats for boards, components, and finished assemblies. These materials help prevent latent damage that can lead to failures in the field.

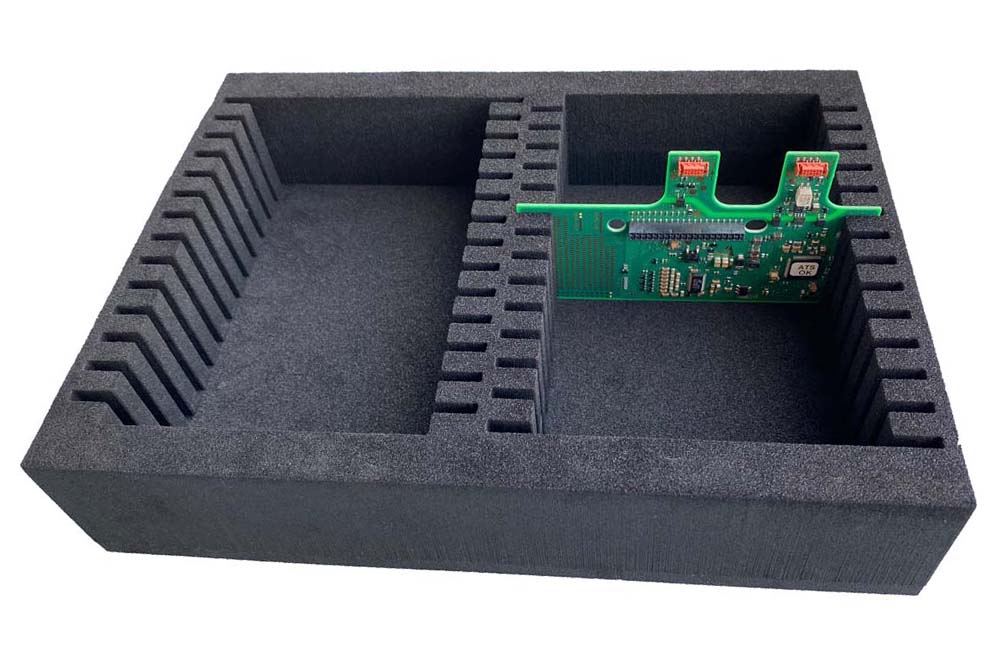

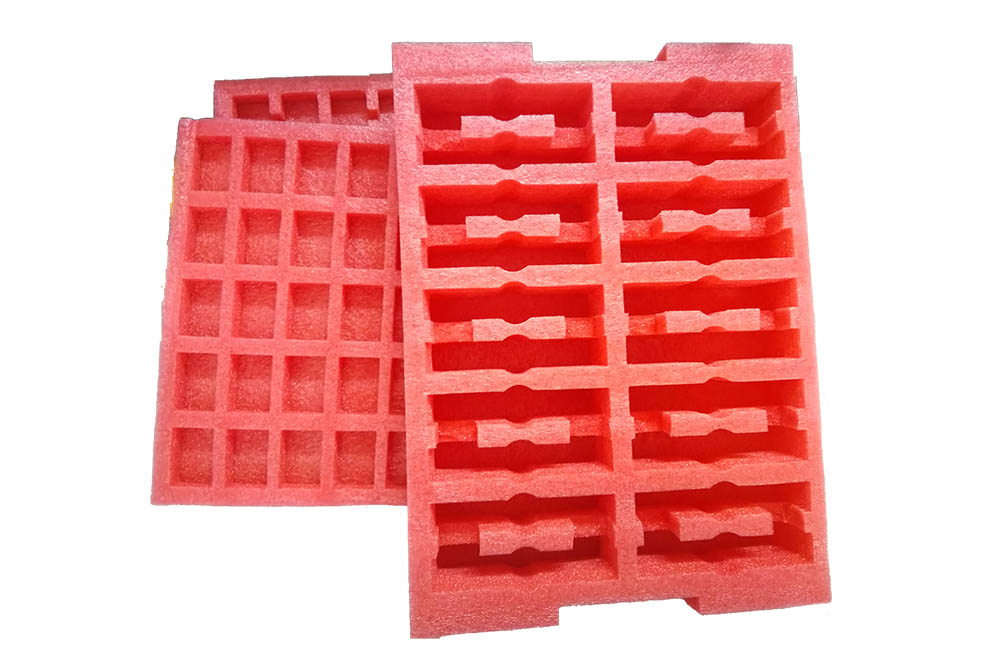

Foam packaging provides both cushioning and ESD protection when properly selected. We supply conductive and dissipative foams that secure sensitive parts while controlling static buildup. These materials are commonly used for circuit boards, connectors, and delicate electronic assemblies that require both protection and organization.

When stock packaging is not enough, custom foam inserts provide precise fit and repeatable protection. We design engineered cushioning that controls movement, absorbs shock, and speeds pack-out for electronics shipments. Custom inserts reduce handling errors, improve consistency, and protect products through long or complex transit routes.

Corrugated boxes provide structure and stacking strength for electronics shipping. We supply standard and custom corrugated shippers, partitions, and inner packs designed to protect products from compression and vibration. Custom sizing reduces void space, improves pallet density, and lowers freight costs while keeping electronics secure from dock to destination.

Moisture can damage sensitive electronics during storage and transit. We supply desiccants and humidity indicators when needed to help control moisture exposure inside sealed packaging. These materials are commonly used for long-distance shipping, overseas transit, and sensitive electronic assemblies.

OEM Materials supports a wide range of electronics operations, including:

We supply electronics packaging that protects components during assembly, storage, and shipping, while ensuring consistent pack-out and reducing handling damage.

We provide flexible packaging solutions that support high-mix, fast changeovers, and repeatable workflows without slowing production.

We supply ESD-safe materials that protect sensitive parts during shipping and internal transfers between facilities.

We help protect finished products during distribution, preventing damage that leads to returns or warranty claims.

We supply packaging that protects electronics during inbound and outbound shipments, improving consistency and reducing failures.

We supply packaging materials that protect electronics during storage, picking, and shipping while supporting efficient handling.

We work with both high-volume manufacturers and specialty electronics companies, providing packaging materials that match their production and distribution needs.

Tell us what electronics you ship, how they move, and where failures occur. Our electronics packaging team will review your needs and provide a clear quote for the right electronics packaging, whether you need stock supplies, custom protection, or a full packaging program.

We improve cushioning, box strength, and load stability to reduce shock and vibration damage during shipping.

We select the right ESD materials to control static discharge and protect sensitive components from latent damage.

Standardized packaging materials reduce decision-making at the workstation and improve throughput for high-volume operations.

We use desiccants and barrier materials to protect electronics from humidity during long transit or storage.

When stock packaging is not enough, we support custom packaging programs. This may include custom foam inserts, ESD-safe materials, partitions, or engineered cushioning designed around your product and process. Custom packaging reduces waste, improves protection, and makes pack-out easier for your team.

We document packaging specifications so your operation can scale without confusion or inconsistency. Custom packaging should simplify operations, not complicate them.

Electronics operations cannot afford packaging shortages. We support customers across the U.S. with reliable delivery and replenishment programs that keep materials available when needed. Our supply programs help prevent overstocking while eliminating last-minute shortages.

Whether you operate from one facility or many, we help maintain consistent packaging materials across your network.

Electronics companies choose OEM Materials because we understand the risks of damage, failure, and returns. We focus on packaging materials that perform in real environments and support predictable, efficient operations.

Our customers rely on us for:

Consistent ESD-safe packaging quality

Reduced damage and failures

Faster, more reliable pack-out

Improved product protection and presentation

Nationwide supply support

If you need dependable electronics packaging that reduces damage and improves efficiency, we can help. Talk to our team for recommendations based on your product, shipping method, and volume.

OEM Materials supplies ESD-safe bags, anti-static and shielding materials, conductive and dissipative foam, custom foam inserts, corrugated boxes, partitions, desiccants, stretch film, tape, and pallet containment supplies. These materials protect electronics from shock, vibration, static discharge, and moisture during storage, handling, and shipping. We support both stock packaging and custom solutions for manufacturers and distributors.

Yes. We provide a full range of ESD-safe packaging, including anti-static bags, shielding bags, conductive foam, and dissipative materials. These products help prevent electrostatic discharge that can damage sensitive components during handling, packing, and transport. Our team helps select the right ESD protection based on your product type, sensitivity level, and workflow requirements.

Yes. We design custom foam inserts that hold electronics securely, control movement, and absorb shock during shipping. Custom inserts improve protection, speed pack-out, and reduce handling errors by giving each part a defined place. We engineer foam based on product size, weight, fragility, and shipping conditions to ensure repeatable, reliable protection.

We reduce damage by improving cushioning, box strength, load stability, and ESD control. Our team reviews how your products move through handling and transit, then recommends packaging that limits vibration, prevents shifting, and protects against static and moisture. Better packaging reduces returns, rework, and warranty claims while improving overall shipping consistency.

Yes. We supply packaging materials that support high-volume, repeatable production environments. Our solutions help standardize pack-out, reduce downtime, and keep materials available through replenishment programs. Whether you ship thousands of units per day or manage multiple facilities, we help maintain consistent packaging that scales with your production needs.

Yes. We supply desiccants, humidity indicators, and barrier materials to help control moisture inside sealed packaging. These solutions protect electronics from corrosion, condensation, and environmental damage during storage and transit. Moisture control is especially important for long-distance shipping, overseas transport, and sensitive electronic assemblies.

Yes. We work closely with EMS providers and contract manufacturers that require flexible, fast-moving packaging solutions. Our materials support high-mix production, frequent changeovers, and consistent workflows without slowing operations. We help reduce packaging errors, improve handling efficiency, and maintain protection across different product types and customers.

Yes. We help customers standardize packaging materials and specifications across multiple plants, warehouses, and distribution centers. Standardization improves consistency, reduces errors, and simplifies training. We document packaging specs and manage supply programs so every location uses the same materials and protection methods.

Yes. OEM Materials supports electronics manufacturers and distributors across the United States. Our nationwide supply and replenishment programs help prevent shortages while avoiding overstocking. We work with customers that operate from single facilities or multiple locations, ensuring consistent packaging availability wherever they ship from.

Getting started is simple. Contact our team and tell us what you ship, how it moves, and where problems occur. We review your current packaging and recommend stock or custom solutions that improve protection and efficiency. You’ll receive a clear quote and a packaging plan designed for your operation.