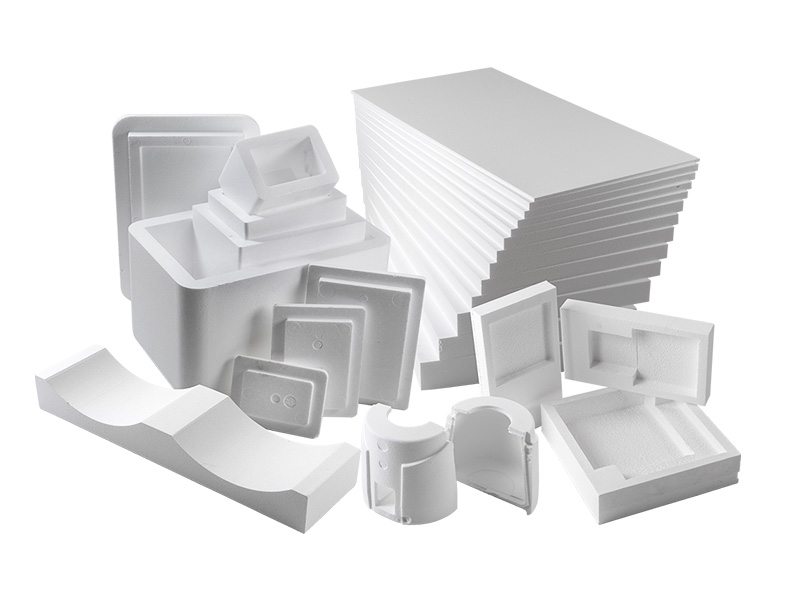

OEM Materials provides industrial-grade foam packaging engineered to protect sensitive components from shock, vibration, abrasion, and impact across manufacturing, assembly, and shipping environments. From CNC-routed inserts to molded foam systems, our protective packaging delivers consistent, repeatable performance for high-value and fragile products.

Below is a comprehensive list of our custom foam packaging products, each designed for precision protection, faster pack-out, and consistent performance in demanding production and shipping environments.

Precision-cut foam designed to match every contour of your product. Die-cut inserts improve protection, streamline pack-out, and ensure consistent orientation during assembly or shipping. Ideal for electronics, instruments, and components requiring exact placement and cushioning.

Custom end-cap cushioning engineered to absorb shock, vibration, and drop impact. End caps maintain safe spacing inside the carton, preventing edge damage and ensuring the product floats securely during transit.

Versatile foam sheets and pads used for blocking, bracing, layering, lining, and work-in-process protection. Ideal for production packaging, kitting operations, and multi-use cushioning applications across industrial and OEM environments.

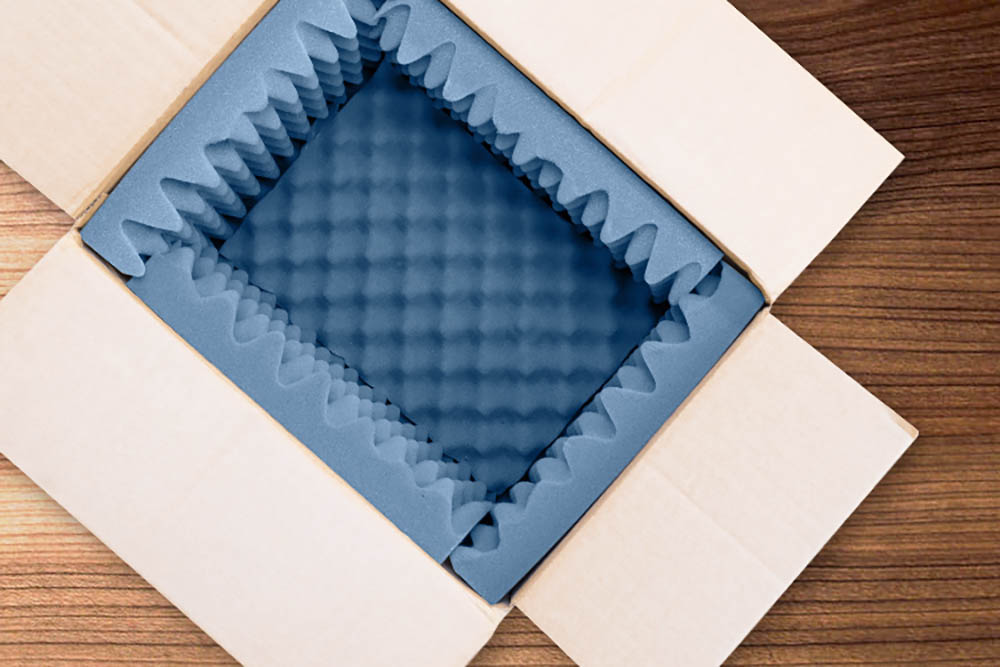

Egg-crate style cushioning that distributes impact forces and supports lightweight, irregular, or delicate items. Common in shipping cases, medical kits, electronics packaging, and instrument protection applications.

Rigid molded foam with a high strength-to-weight ratio for impact resistance. EPS is commonly used for appliances, electronics, and export packaging where lightweight, high-strength cushioning is essential.

Durable molded foam with high recovery and resistance to crushing. Ideal for reusable packaging, automotive components, aerospace builds, and programs requiring long-term durability and repeated use.

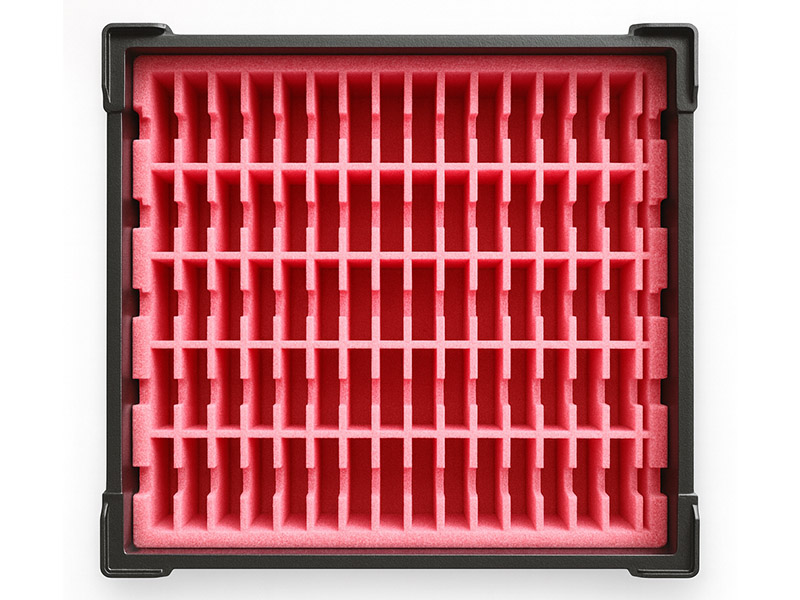

Static-safe foam designed to protect electronic components, PCBs, and semiconductor assemblies. Prevents electrostatic discharge while providing secure, custom-tailored cushioning for trays, kits, and shipping containers.

Pressure-sensitive adhesive–laminated foam for fast installation without hardware. Ideal for cases, totes, fixtures, racks, and equipment surfaces where cushioning or noise reduction is required.

Soft, flexible cushioning foam for delicate instruments, cosmetic-sensitive items, and tool control applications. Ideal for applications requiring gentle contact surfaces and custom color options.

Closed-cell, moisture-resistant foam that provides excellent shock absorption and surface protection. Used widely across industrial, aerospace, medical, and general manufacturing applications.

Premium fine-cell closed-cell foam offering superior durability, chemical resistance, and high-end appearance. Ideal for reusable packaging, medical equipment, aerospace kits, and presentation-quality applications.

Two-piece engineered cushioning systems designed to suspend and “float” products inside the box. Absorbs multi-directional impact forces and prevents damage during heavy shipping and handling.

Every foam solution is built to absorb shock, prevent movement, and protect sensitive components during storage, handling, and shipment.

Foam is precision-cut, molded, or routed to match exact product shapes, reducing movement, improving pack-out speed, and ensuring consistent orientation.

We combine foam with corrugated, plastics, and custom hardware for complete packaging systems that simplify assembly and reduce labor.

Our foam solutions reduce shipping weight without sacrificing strength, lowering freight costs and improving overall material efficiency.

Every foam component is engineered for reliable fit, predictable cushioning performance, and seamless integration with your production and kitting workflows.

Protective foam packaging is essential for safeguarding high-value, fragile, and precision-built products. At OEM Materials, we engineer foam systems that provide predictable cushioning, stable product orientation, and consistent protection throughout production and shipping environments. Our foam is selected and manufactured based on density, recovery, durability, and application-specific requirements.

From die-cut inserts to molded impact-resistant components, each foam solution is designed to reduce damage, streamline pack-out, improve workflow reliability, and support multi-stage manufacturing. Whether you need cushioning for electronics, medical devices, aerospace assemblies, or industrial components, our foam packaging is tailored to meet the exact performance needed for your operation.

High-performance foam engineered for fragile assemblies, mission-critical components, and export packaging requiring precise cushioning and compliance.

Clean, consistent foam systems that protect sterile, delicate, and regulated products used in medical kits, trays, and diagnostic equipment.

Impact-resistant and ESD-safe foam solutions that protect sensitive electronic components from physical and electrostatic damage.

Custom foam inserts designed for subassemblies, component staging, work-in-process protection, and efficient production flow.

Durable foam cushioning that withstands vibration, weight loads, and rugged handling across industrial machinery, mechanical parts, and metal components.

Presentation-quality foam for retail packaging, cases, instruments, and high-end consumer goods requiring both protection and visual appeal.

Flexible, adaptable foam solutions that support frequent SKU changes, varied dimensions, and high-volume kitting requirements.

OEM Materials is here to help you design, source, and integrate corrugated packaging solutions that improve protection, reduce cost, and streamline production.

We supply precision foam packaging to manufacturers and distributors across the United States, supporting demanding industrial and high-value shipping environments.

With distribution centers in California, Illinois, Pennsylvania, Texas, and Georgia, we provide reliable replenishment and shorter lead times.

Whether you operate a single facility or multiple plants, we coordinate shipments and maintain foam inventory to prevent stockouts.

Facilities near our distribution centers benefit from quicker shipments and rapid access to replenishment ideal for fast-moving operations.

We provide custom foam solutions suited for global transport, protecting sensitive components during long-distance shipment and handling.

From precision-cut foam inserts to molded cushioning systems, OEM Materials delivers engineered protection your operation depends on.

OEM Materials offers a full range of engineered foam solutions including die-cut inserts, molded EPS, EPE/EPP, polyurethane, polyethylene, crosslinked XLPE, convoluted foam, end caps, adhesive-backed foam, and top/bottom cushioning. Each material is selected for density, durability, and impact performance to match the exact protection your product requires.

Our team reviews your product geometry, fragility, shipping conditions, and workflow to recommend the correct foam type. Factors like weight, vibration exposure, surface sensitivity, and handling requirements guide the selection. We help you choose the ideal density, structure, and cushioning performance to ensure proper protection and pack-out efficiency.

Yes. We specialize in custom-cut, CNC-routed, and molded foam inserts engineered to match the exact contours of your product. Custom shaping improves protection, orientation, and repeatability during pack-out. This is especially useful for medical devices, electronics, instruments, and multi-component kits that require precision and stable positioning.

We offer Anti-Static and ESD-safe foam specifically engineered to protect sensitive electronics, PCBs, chips, and semiconductor components. These foams prevent electrostatic discharge while providing secure cushioning. They can be designed for trays, shipping containers, kitting systems, and cleanroom workflows where static control is essential.

Yes. We provide durable foams such as EPE, EPP, PE, and XLPE that withstand repeated impacts and maintain shape across multiple cycles. These materials are ideal for reusable totes, racks, work-in-process protection, and long-term packaging systems used in automotive, aerospace, and high-mix production environments.

Absolutely. We design multi-material packaging systems that combine foam with corrugated, plastics, hardware packs, and custom assemblies. This approach reduces labor, improves efficiency, and ensures each component works together for consistent pack-out. Complete kits are available for production lines, assembly, and shipping applications.

Yes. We provide clean, low-particulate foam materials suitable for medical devices, diagnostic kits, sterile packaging, and controlled environments. Our foam inserts can be designed to fit trays, cases, and assembly workflows while supporting compliance, cleanliness, and delicate handling requirements common in life sciences.

Our foam end caps and cushioning systems are engineered to absorb shock, resist crushing, and protect products during heavy movement, vibration, and stacking. Depending on the material selected, these systems can provide high recovery, long-term durability, and excellent protection for repeated or long-distance shipping.

Yes. OEM Materials provides prototyping and testing support to ensure the foam meets performance expectations. We validate fit, cushioning performance, drop resistance, and usability during pack-out. Adjustments can be made before full production to ensure proper protection, efficiency, and material optimization.

Lead times vary by foam type and complexity, but our regional distribution centers in CA, IL, PA, TX, and GA enable fast national delivery. Stock materials can ship quickly, and custom foam projects are produced efficiently. For ongoing needs, VMI and JIT programs ensure continuous availability without stockouts or production delays.