OEM Materials provides industrial-grade crate systems designed to protect, secure, and stabilize sensitive products during shipping, storage, and global transport. From mil-spec defense crates to collapsible warehouse systems, our wood and plastic crates are engineered for durability, efficiency, and consistent performance across demanding environments.

Below is a comprehensive list of our engineered crate solutions, each designed for strength, cushioning, and reliable protection in manufacturing, logistics, and export workflows.

Rugged wood crates lined with engineered foam to protect sensitive and high-value components. We pair the correct crate construction with the right foam density to control shock, vibration, and abrasion—ideal for electronics, aerospace hardware, medical devices, and precision assemblies.

Custom wood crates equipped with precision die-cut foam cavities that locate and support every part. These inserts improve pack-out repeatability, reduce handling time, and dramatically cut transit damage—perfect for multi-component systems and high-value machinery.

Defense-grade wood crates built to meet strict military packaging specifications. We follow applicable MIL-STD requirements for materials, fasteners, blocking, bracing, markings, and construction, ensuring mission-critical equipment ships safely and passes inspection.

Cost-effective single-use crates designed for one-way shipments and export programs. Built to protect products throughout their journey and then be easily broken down or recycled at destination. Ideal for contract manufacturing, product launches, and project-based shipping.

Space-saving knock-down crate systems that ship and store flat to reduce freight and warehouse costs. These reusable designs assemble quickly as needed, then collapse for storage—perfect for recurring programs, returns, trade shows, and tight warehouse environments.

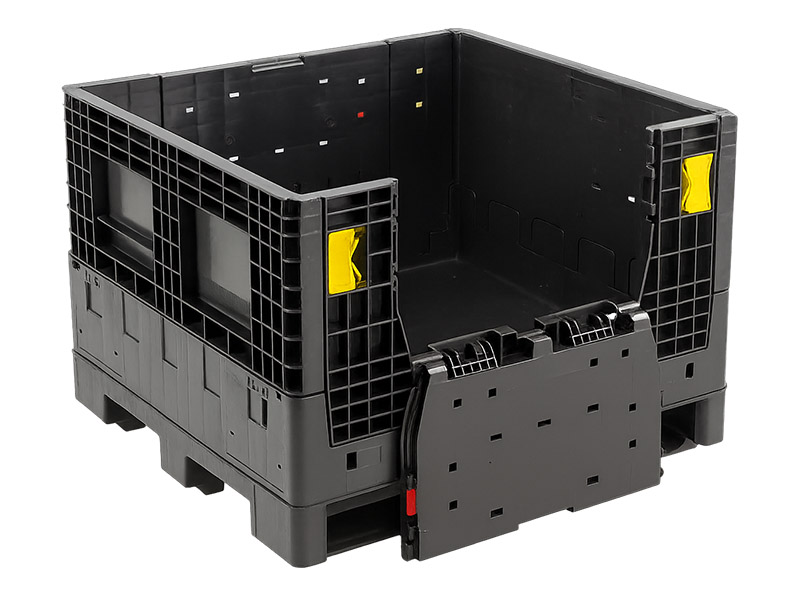

Durable, reusable plastic crates engineered for clean, closed-loop workflows. Resistant to moisture, contamination, and impact, these crates are ideal for medical, food, electronics, and warehouse operations. Stackable and nestable designs maximize cube efficiency and reduce damage.

Every crate is engineered to withstand heavy handling, stacking, vibration, and real-world logistics demands.

We design crates and foam systems around exact product geometry to reduce movement, increase protection, and improve pack-out repeatability.

Heat-treated ISPM-15 options and full mil-spec capabilities ensure your shipments clear inspection and arrive safely worldwide.

We combine wood, plastics, engineered foam, hardware, fasteners, and custom interiors into complete, ready-to-deploy crating solutions.

Every crate is built for dimensional accuracy, reliable stacking strength, and predictable protective performance across every order.

Crates are essential for protecting high-value, fragile, and industrial products during storage, handling, and global transport. At OEM Materials, we engineer crate systems that go far beyond standard wood boxes. Each solution is designed for structural integrity, shock control, and repeatable protection across demanding manufacturing and export workflows.

Our crate systems are built using high-strength materials, precision interiors, and application-specific design standards. Whether you’re shipping oversized machinery, sensitive electronics, aerospace assemblies, or medical equipment, every crate is tailored for the right balance of strength, cushioning, and handling efficiency.

From collapsible reusable crates to mil-spec export systems, we provide complete solutions that reduce damage, streamline pack-out, improve load stability, and support national and global supply chains.

Engineered crates designed to protect mission-critical components with foam interiors, export-ready compliance, and mil-spec construction.

Clean, secure crate solutions for sterile, delicate, and regulated medical equipment requiring consistent cushioning and safe global transit.

Precision crating systems that protect sensitive electronics from shock, vibration, and moisture. Ideal for high-value instruments and assemblies.

Custom crates built to fit complex assemblies, subcomponents, and machinery. Designed for workflow efficiency and long-distance transport.

Durable crates capable of handling heavy equipment, rugged parts, and mechanical assemblies. Built for strength, stability, and repeatable use.

Presentation-grade crate options with foam interiors for retail fixtures, instruments, and high-end goods requiring elevated protection.

Flexible crate systems for frequent SKU changes, varied product sizes, and fast-cycle workflows requiring consistent performance.

OEM Materials is here to help you design, source, and integrate crate solutions that improve protection, reduce damage, and support domestic and international shipping.

We supply custom and stock crate solutions to manufacturers, distributors, and export operations across the United States.

With distribution centers in CA, IL, PA, TX, and GA, we provide shorter lead times and dependable replenishment.

We coordinate deliveries and maintain consistent stock for single-site and multi-facility operations.

Facilities near our distribution centers benefit from accelerated shipments, reduced downtime, and quicker crate replenishment.

We provide export-ready and ISPM-15 compliant crates built for global transport and rugged logistics environments.

From foam-lined export crates to collapsible warehouse systems, OEM Materials delivers the engineered crating solutions your operation depends on.From foam-lined export crates to collapsible warehouse systems, OEM Materials delivers the engineered crating solutions your operation depends on.

OEM Materials provides a complete range of engineered crate solutions, including foam-lined crates, die-cut foam insert crates, mil-spec wood crates, single-use crates, collapsible knock-down crates, and reusable plastic crates. Each type is designed to protect products during storage, handling, long-distance shipping, and global transport.

Our team evaluates your product’s size, weight, fragility, and shipping conditions to recommend the ideal crate type. We consider factors like vibration exposure, stacking requirements, mode of transport, and whether foam, partitions, or die-cut inserts are needed. This ensures the crate delivers the right balance of strength, cushioning, and handling efficiency.

Yes. We specialize in crates with custom foam interiors, including die-cut, CNC-routed, and molded foam options. Each cavity is engineered to match the exact geometry of your product, improving protection, pack-out speed, and repeatability. Foam interiors help control shock, vibration, and movement during domestic and international shipping.

Absolutely. We manufacture mil-spec compliant crates built to meet applicable military standards for materials, blocking, bracing, hardware, and markings. These crates are designed for mission-critical equipment and undergo strict construction requirements to ensure compliance, safe handling, global shipment readiness, and inspection approval.

Yes. We offer export-ready crate solutions including heat-treated ISPM-15 compliant wood and heavy-duty designs built to withstand long-distance handling. Our crates are engineered to resist moisture, stacking pressure, and vibration during global transit, ensuring your equipment arrives safely and meets international shipping regulations.

We provide collapsible and reusable crate systems that assemble quickly when needed and break down flat after use. These crates reduce warehouse storage space, cut freight costs, and support recurring programs, returns, trade shows, and closed-loop logistics. They’re ideal for operations that need durability without permanent bulk.

Yes. We design and manufacture crates for large, heavy, and irregular-shaped products that require reinforced construction. Options include heavy-duty hardware, custom blocking and bracing, foam suspension systems, and pallet-base builds. Each crate is engineered to handle weight loads, machinery footprints, and demanding transit environments.

Yes. Our plastic crates are ideal for cleanrooms, medical facilities, food operations, electronics manufacturing, and environments where wood isn’t appropriate. Plastic crates resist moisture, contamination, and splintering. Stackable or nestable designs help maximize cube, reduce damage, and support long-term, closed-loop workflows.

We provide prototyping, sample builds, and design validation to ensure your crate performs exactly as intended. Testing may include fit checks, cushioning performance, shock/vibration behavior, and usability during pack-out. Adjustments can be made before full production to guarantee protection, efficiency, and compliance requirements are met.

Lead times depend on crate type, volume, foam interior complexity, and regulatory needs such as ISPM-15 or mil-spec requirements. With distribution centers in CA, IL, PA, TX, and GA, we offer fast regional and nationwide delivery. For ongoing programs, we support VMI, JIT, and scheduled production to prevent delays and stockouts.