OEM Materials supplies aerospace packaging products designed to protect high-value components through manufacturing, storage, and transit. Our materials support repeatable processes, reduce handling risk, and maintain part integrity across long, complex supply chains. From engineered cushioning to corrosion control and load containment, we deliver packaging that performs in real aerospace environments.

Aerospace packaging must protect more than parts; it must protect performance, safety, and program timelines. Components face long transit cycles, strict handling requirements, repeated movement, and zero tolerance for damage. At OEM Materials, we supply aerospace packaging materials designed for real manufacturing, MRO, and distribution environments, not controlled lab conditions. Our customers rely on consistent packaging performance to reduce risk, prevent rework, and maintain compliance. We support aerospace manufacturers, defense contractors, and aviation suppliers across the United States with dependable packaging solutions that scale with production volume, program complexity, and delivery demands.

OEM Materials designs custom foam and engineered cushioning that protects aerospace components from shock, vibration, and movement during handling and transit. We create precise fits that support critical surfaces, maintain orientation, and prevent damage to high-value parts. These solutions improve pack-out consistency, reduce handling errors, and support repeatable processes for manufacturing, MRO, and distribution operations across the aerospace supply chain.

Our heavy-duty corrugated boxes provide the structural strength needed for aerospace components during storage and shipping. Designed to resist compression and vibration, these boxes protect parts through long transit cycles and multiple handling points. Custom sizing reduces void space, improves pallet stability, and lowers freight risk while maintaining consistent protection from dock to destination.

OEM Materials supplies heavy-duty wooden crates for oversized, heavy, or high-value aerospace components. These crates provide rigid protection, load stability, and impact resistance for domestic and international shipments. We design crates to support blocking and bracing, protect critical surfaces, and meet the demands of long-distance transport, storage, and complex logistics environments.

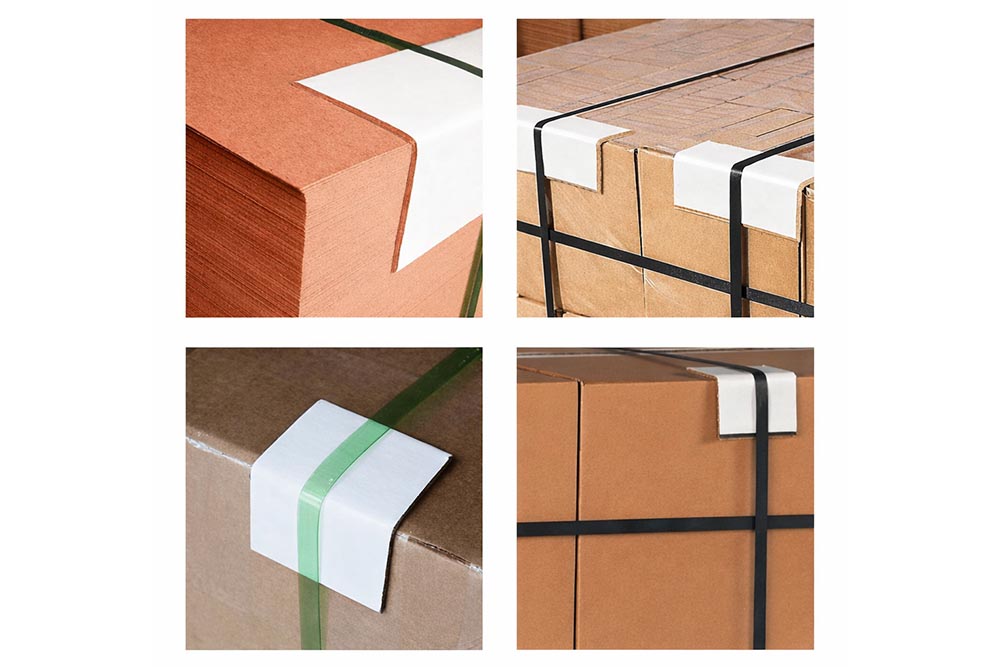

Edge protection and strapping materials help maintain load integrity for aerospace shipments that move through multiple handling stages. We supply corner protectors, steel and plastic strapping, and stretch wrap systems that reinforce pallets, protect edges, and reduce shifting during transit. These materials improve safety, minimize damage, and support consistent load containment across your operation.

Partitions and specialty packs keep aerospace components organized, separated, and protected during storage and shipment. These solutions prevent part-to-part contact, maintain orientation, and protect sensitive surfaces. Ideal for kits, assemblies, and multi-part shipments, specialty packaging improves pack-out efficiency, reduces errors, and ensures components arrive ready for use or installation.

OEM Materials supports a wide range of aerospace operations, including:

We supply packaging that protects components during production, storage, and shipping while supporting consistent pack-out and reducing handling risk.

We provide protective packaging that supports strict handling requirements, traceability, and reliability for sensitive aerospace and defense programs.

We supply packaging materials that protect precision parts during transit and internal transfers between facilities, preventing damage and rework.

We help protect finished assemblies during distribution, reducing damage that causes delays, rejections, or costly rework.

We supply packaging that protects parts through repeated shipping cycles, internal movement, and long-term storage.

We provide packaging materials that protect components during storage, picking, and outbound shipments while supporting efficient, repeatable handling.

We work with both high-volume aerospace programs and specialized suppliers, delivering packaging materials that match production, compliance, and logistics requirements.

Tell us what aerospace components you ship, how they move, and where damage or delays occur. Our aerospace packaging team will review your requirements and provide a clear quote for the right packaging solution, whether you need stock materials, custom protection, or a complete aerospace packaging program.

We improve cushioning, packaging strength, and load stabilization to protect aerospace components from shock, vibration, and impact during transit.

We design packaging that supports sensitive features and prevents abrasion, deformation, or movement during handling and shipping.

Standardized packaging materials reduce variation at the workstation and improve speed, accuracy, and repeatability for aerospace operations.

We use desiccants, barrier films, and VCI materials to protect aerospace components from humidity and corrosion during long transit or storage.

When stock packaging is not enough, we support custom aerospace packaging programs. This may include custom foam inserts, engineered cushioning, reinforced corrugated boxes, wood crating, partitions, or corrosion protection designed around your components and workflow. Custom packaging reduces waste, improves protection, and makes pack-out easier for your team.

We document packaging specifications so your operation can scale without confusion or inconsistency. Custom aerospace packaging should simplify operations, not complicate them.

Aerospace operations cannot afford packaging shortages or inconsistency. We support customers across the U.S. with reliable delivery and replenishment programs that keep materials available when needed. Our supply programs help prevent overstocking while eliminating last-minute disruptions.

Whether you operate from one facility or many, we help maintain consistent packaging materials across your network.

Aerospace companies choose OEM Materials because we understand the cost of damage, delays, and non-compliance. We focus on packaging materials that perform in real manufacturing, MRO, and distribution environments while supporting predictable, efficient operations.

Our customers rely on us for:

Consistent, high-quality aerospace packaging

Reduced damage, rework, and shipping risk

Faster, more reliable pack-out

Improved component protection and presentation

Nationwide supply and replenishment support

If you need dependable aerospace packaging that reduces risk and improves efficiency, we can help. Talk to our team for recommendations based on your components, shipping methods, and production volume.

OEM Materials supplies custom foam and engineered cushioning, heavy-duty corrugated boxes, wood crates as needed, partitions and specialty packs, edge protection, strapping, and stretch wrap. We also provide blocking and bracing plus corrosion and moisture control with VCI materials, desiccants, and indicators. We help you choose the right combination for your part, route, and handling points. We support both one-off needs and ongoing programs with repeatable performance.

Yes. We design custom foam inserts that match your part geometry, weight, and handling needs. We add support points to protect critical surfaces, control orientation, and reduce movement that causes abrasion or impact damage. We can build in pockets for hardware, labels, or documents to improve traceability. Custom inserts standardize pack-out and improve repeatability across shifts and sites. We can prototype, refine fit, and scale production so packaging stays consistent over time.

Use heavy-duty corrugated when you need strong, stackable protection with lower weight, faster handling, and efficient pallet density. Choose a wooden crate when parts are oversized, very heavy, fragile, or must withstand long transit, multiple transfers, or export conditions. We review your component, shipping mode, and risk points, then recommend structure, reinforcement, and internal stabilization. If requirements change, we adjust materials and dimensions to keep protection and efficiency balanced.

Yes. We supply blocking and bracing materials and layouts that prevent shifting, tipping, and vibration damage. We size and place supports to stabilize loads inside boxes or crates while protecting sensitive features and finishes. Proper blocking and bracing improves handling safety, reduces transit claims, and helps parts arrive ready for receiving inspection, assembly, or installation with minimal rework. We can also support load diagrams and packing instructions so teams brace the same way every time.

We use corrosion and moisture control products such as VCI films and papers, barrier materials, desiccants, and humidity indicators. We select protection based on alloy type, surface finish, storage duration, and transit route. We also help you seal and stage packs correctly so protection stays effective. These solutions reduce oxidation risk and protect aerospace parts during long-distance shipping and storage. For long routes, we can combine barrier packaging with desiccants and VCI to extend protection duration.

Yes. We standardize materials, define pack-out steps, and design packaging that is easy to repeat. Custom inserts, partitions, and properly sized shippers reduce decision-making at the workstation and limit part movement. We can document specs, photos, and material callouts so teams pack the same way every time. Consistent packaging lowers handling errors, reduces rework, and improves throughput. If you ship from multiple locations, documentation helps you maintain the same pack-out across the network.

Absolutely. We provide partitions and specialty packs that separate components, prevent part-to-part contact, and maintain orientation. These solutions work well for kits, assemblies, and multi-part shipments where organization and presentation matter. We can design packs to support quick counts, clean labeling, and safer handling. Better organization speeds picking and pack-out and helps receiving teams inspect parts efficiently. We also help you reduce waste by right-sizing packs and eliminating unnecessary void fill.

We supply edge protectors, steel or plastic strapping, stretch wrap, and related accessories to reinforce pallet loads. These materials protect edges, reduce crushing, and keep loads stable through repeated handling. We help you match containment to weight, pallet pattern, and shipping method, and we can recommend blocking or bracing where needed. Strong containment reduces damage risk and improves safety at every touchpoint. We also advise on edge protection sizing and strapping tension to avoid crushing or deformation.

Yes. We support customers across the U.S. with dependable shipping and replenishment programs. We help you set min/max levels, standardize SKUs, and keep consistent materials across multiple sites. Replenishment reduces last-minute shortages while avoiding excess inventory, so production stays on schedule. If you run multiple programs, we can align packaging specs and substitutions to reduce variation. We can set up scheduled deliveries and consolidated shipments to keep critical supplies available.

Start with a quick review of what you ship, how it moves, and where damage, corrosion, or delays occur. Share part dimensions, weights, quantities, and any handling, cleanliness, or storage constraints. Our team recommends stock materials or designs a custom solution, then provides a clear quote. We can document packaging specifications and support rollout so your process stays consistent as volumes and locations scale. If you send photos or samples, we can identify quick wins and recommend next steps without slowing production.