OEM Materials provides industrial-grade corrugated packaging designed to support manufacturing, distribution, export, and high-value product movement. From custom-sized cartons to heavy-duty triple-wall builds, our corrugated box solutions are engineered for durability, efficiency, and consistent performance across demanding environments.

Below is a comprehensive list of our corrugated packaging solutions, each engineered to support manufacturing, shipping, and material-handling operations.

Built to your exact dimensions, strength, and printing requirements. From small RETT mailers to oversized Gaylords, we produce corrugated systems that match your product’s geometry and handling needs. Custom printing up to four colors enhances branding, identification, and workflow efficiency.

A lightweight, cost-effective option for everyday packaging, shipping, and storage. Ideal for e-commerce, retail, and general production material flow. Manufactured to your required strength and board grade for reliable performance.

Engineered with two layers of corrugated board for added rigidity, stacking strength, and impact resistance. Perfect for industrial components, bulk parts, mechanical assemblies, and heavier product loads that require more robust protection.

Maximum-strength corrugated built for heavy, large, or high-value shipments. Often used as an alternative to wood crates, triple-wall reduces weight and freight cost while maintaining exceptional durability for domestic and export handling.

Designed to withstand moisture, humidity, temperature swings, and outdoor storage conditions. These boxes retain structural integrity even when exposed to condensation or harsh distribution environments—ideal for export and long-term warehousing.

Complete box + divider systems engineered to eliminate product movement and reduce damage. Perfect for multi-component assemblies, fragile items, glass, electronics, and any product that requires separation during shipping or storage.

Oversized corrugated solutions designed for palletized transport of bulk parts, scrap, powders, liquids, and finished goods. Engineered for warehouse stacking, high-volume handling, and large-capacity storage.

Custom-sized self-locking mailers for secure, professional presentation of small goods, components, and kits. Available with inside/outside printing for enhanced branding and customer experience. Ideal for direct-to-consumer shipments and small industrial parts.

Two-piece adjustable carton system that expands or contracts to fit variable product heights. Perfect for long, flat, or fragile items such as signage, panels, equipment, or irregular goods—without the need for excess filler or void space.

Certified, regulation-compliant boxes for transporting hazardous materials. Designed, tested, and built to meet strict UN/DOT performance requirements, ensuring safe, legal shipment of chemicals, liquids, batteries, and other regulated materials.

Every box is engineered to meet the handling, stacking, and durability demands of real production environments.

Right-sized corrugated reduces void space, improves pack-out efficiency, and lowers material waste.

Available custom printing—inside or outside—supports brand visibility, lot tracking, and operational clarity.

From ISPM alternatives to weather-resistant grades, our solutions meet the needs of national and international supply chains.

Our corrugated packaging is manufactured to deliver uniform strength, precise dimensions, and predictable quality across every order.

Corrugated packaging is the backbone of modern manufacturing, logistics, and product distribution. At OEM Materials, we engineer corrugated boxes that go far beyond standard cartons. Each solution is designed to support the real-world demands of industrial operations, high-value product movement, and multi-stage production workflows.

Our corrugated packaging solutions are built for durability, consistency, and precision. Whether you’re shipping heavy mechanical components, organizing sensitive assemblies, managing high-mix part flow, or delivering branded consumer products, every box is tailored to provide the right balance of strength, protection, and efficiency.

We manufacture corrugated packaging in a full range of board grades, wall constructions, and custom configurations, ensuring you always get the exact performance required for your application. From lightweight mailers to triple-wall crates, our corrugated solutions help manufacturers reduce damage, streamline pack-out, improve stacking stability, and optimize material flow across every stage of the supply chain.

Corrugated packaging from OEM Materials supports the demanding requirements of manufacturers, distributors, and high-value product producers across multiple industries. Each solution is engineered to meet the unique performance, strength, and handling needs of your environment.

Heavy-duty corrugated built for mission-critical components, with options like triple-wall cartons, custom partition sets, and export-ready packaging. Designed for strength, compliance, and repeatable protection during storage, transport, and global shipment.

Clean, precise corrugated solutions for sterile, fragile, and regulated medical products. Right-sized cartons, divider sets, and mailers improve handling, prevent damage, and support quality control across cleanroom and assembly workflows.

Corrugated systems engineered for sensitive components and high-value electronics. Pair with ESD-safe materials or custom partitions to protect against vibration, impact, and contamination throughout cleanroom, assembly, and distribution environments.

Custom corrugated boxes that fit build-to-order parts, assemblies, and subcomponents. Designed for efficiency, repeatability, and smoother material flow across high-mix or production-driven manufacturing lines.

Durable, heavy-duty cartons built for rugged handling and high-weight loads. Double-wall and triple-wall systems deliver superior stacking strength for mechanical components, metal parts, machinery, and industrial equipment.

Retail-ready corrugated packaging designed for presentation, branding, and safe transport. Printed mailers, branded cartons, and custom die-cut solutions enhance customer experience while protecting goods during fulfillment and shipping.

Flexible corrugated solutions designed to handle frequent SKU changes, varied product dimensions, and fast production cycles. Right-sized cartons and partition sets improve pack-out consistency and reduce labor across shifting workflows.

OEM Materials is here to help you design, source, and integrate corrugated solutions that improve protection, reduce cost, and streamline production.

OEM Materials supplies corrugated boxes and mailer solutions to manufacturers, distributors, and production facilities across the United States. With strategically located distribution centers and reliable national logistics, we ensure fast, consistent delivery of both custom and stock corrugated packaging, no matter where your operation is located.

We support businesses coast-to-coast with durable, custom-engineered corrugated packaging designed for industrial use, high-value shipments, and demanding supply chain environments.

Our distribution centers in California, Illinois, Pennsylvania, Texas, and Georgia allow us to serve major manufacturing and logistics hubs with shorter lead times and dependable replenishment.

Whether you operate one facility or manage a national network of plants, we coordinate deliveries, maintain stock levels, and ensure uninterrupted corrugated supply for every location.

Facilities located near our distribution centers benefit from accelerated shipments, reduced downtime, and quick access to replenishment, ideal for high-mix and fast-moving production environments.

We supply export-ready cartons, triple-wall containers, and weather-resistant corrugated solutions for national and international logistics needs.

From custom corrugated boxes to heavy-duty mailers and export-grade cartons, OEM Materials delivers the custom packaging solutions your operation depends on. Get fast quotes, expert support, and nationwide delivery.

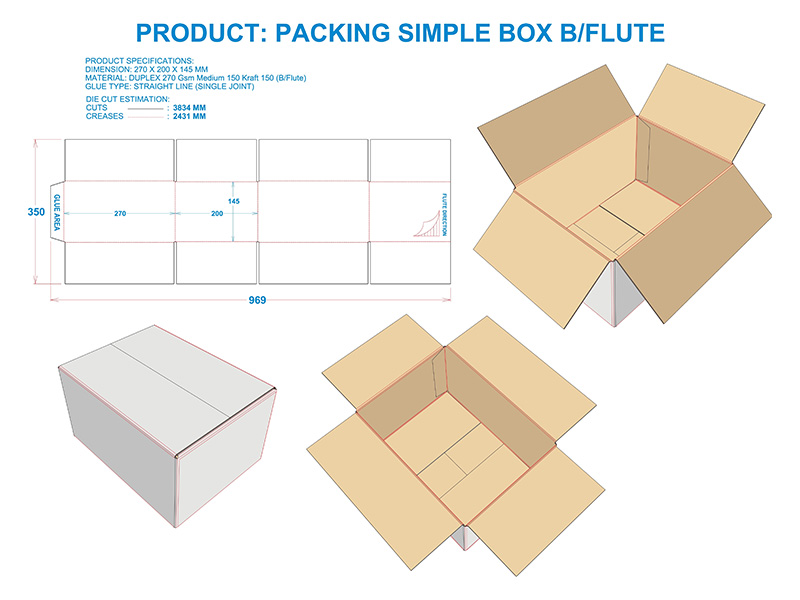

OEM Materials provides a full range of corrugated solutions including custom-size cartons, single-, double-, and triple-wall boxes, weather-resistant grades, partition sets, mailers, Gaylords, telescopic boxes, and UN/DOT-rated haz-mat boxes. Each option is engineered for durability, strength, and efficient handling in manufacturing and distribution environments.

Single-wall is ideal for lightweight items and general shipping. Double-wall provides added strength for heavier or bulkier components. Triple-wall is the strongest option, often replacing wood crates for large, heavy, or high-value shipments. We evaluate your product’s weight, fragility, and shipping conditions to recommend the right wall construction.

Yes. We specialize in producing corrugated boxes built to your exact dimensions, board strength, and printing requirements. Custom sizing reduces void space, improves pack-out consistency, lowers material waste, and ensures the box perfectly supports your product’s geometry. This is especially useful for high-value, fragile, or irregularly shaped items.

We offer custom printing up to four colors, both inside and outside the box. Printing supports branding, lot tracking, part identification, and workflow efficiency. Whether you need branding for customer-facing shipments or functional labeling for internal operations, we can design corrugated packaging that strengthens visibility and professionalism.

We supply corrugated packaging to aerospace, medical devices, electronics, semiconductor, OEM manufacturing, automotive, consumer products, warehousing, and high-mix production environments. Each industry benefits from tailored box strength, custom partitions, weather-resistant grades, and packaging designed for demanding production workflows.

Yes. We offer export-ready solutions including triple-wall boxes, weather-resistant corrugated (W5C/V3C), and custom crates designed for global handling. These boxes withstand stacking, moisture, vibration, and heavy movement across air, sea, or ground transportation. Our export-grade cartons reduce failures during long-distance shipping.

OEM Materials manufactures UN/DOT-rated haz-mat shipping boxes tested for performance, durability, and compliance. These boxes are designed for chemicals, liquids, batteries, powders, and regulated materials that require certified packaging. We ensure every solution meets the strict regulatory standards needed for safe, legal transport.

Unlike off-the-shelf cartons, our corrugated packaging is engineered for industrial environments. We control board grade, wall construction, printing, and dimensional accuracy to ensure consistent performance. Every box is built for real manufacturing workflows, meaning improved stacking strength, reduced damage, and better repeatability across orders.

Yes. We design custom box-and-partition sets that prevent product movement, eliminate contact between components, and reduce damage during transport. These systems are ideal for assemblies, glass, electronics, medical kits, and other items requiring separation. Each partition is engineered around your product geometry for perfect fit and stability.

With distribution centers in California, Illinois, Pennsylvania, Texas, and Georgia, we provide fast regional and nationwide delivery. Lead times vary by box type and volume, but common sizes and stock cartons are shipped quickly. Custom corrugated projects are produced efficiently and supported by VMI or JIT programs to prevent stockouts and delays.