OEM Materials provides complete custom packaging kits designed to reduce damage, increase efficiency, and standardize pack-out across production, distribution, and field service environments. Every kit combines the correct box style with engineered protective components, ensuring consistent, repeatable performance for fragile, high-value, and precision-built products.

Below is a comprehensive selection of our custom made packaging kits, each designed to streamline assembly, reduce labor, and deliver reliable protection throughout handling and shipping.

Pre-assembled cartons lined with PE, EPE, XLPE, or polyurethane foam for advanced shock absorption and vibration control. These cushioned box kits are ideal for aerospace, electronics, medical devices, defense equipment, and high-value industrial components requiring consistent protection during transport and handling.

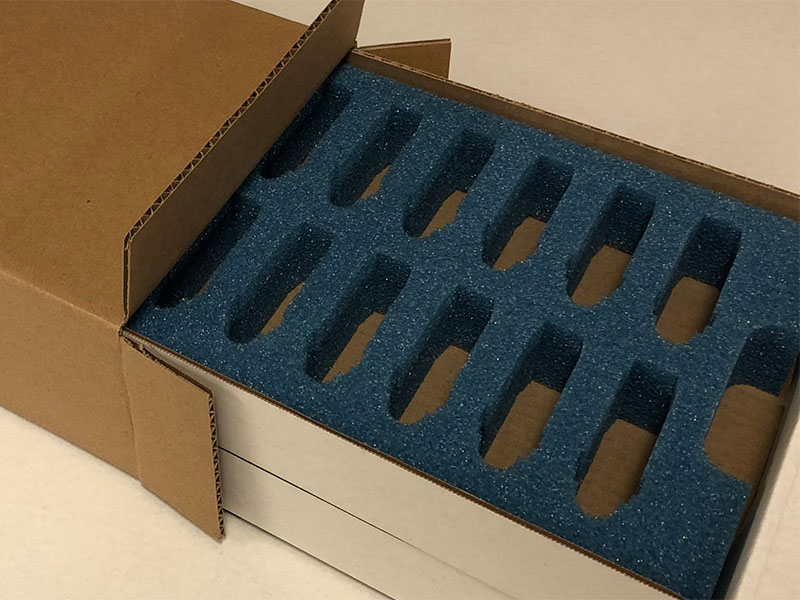

Precision-engineered inserts matched to the exact geometry of your product. Available as CNC-routed, waterjet, laser-cut, or die-cut options paired with corrugated or reusable containers. Perfect for repeat shipments, production lines, and multi-component assemblies where orientation and protection must remain consistent.

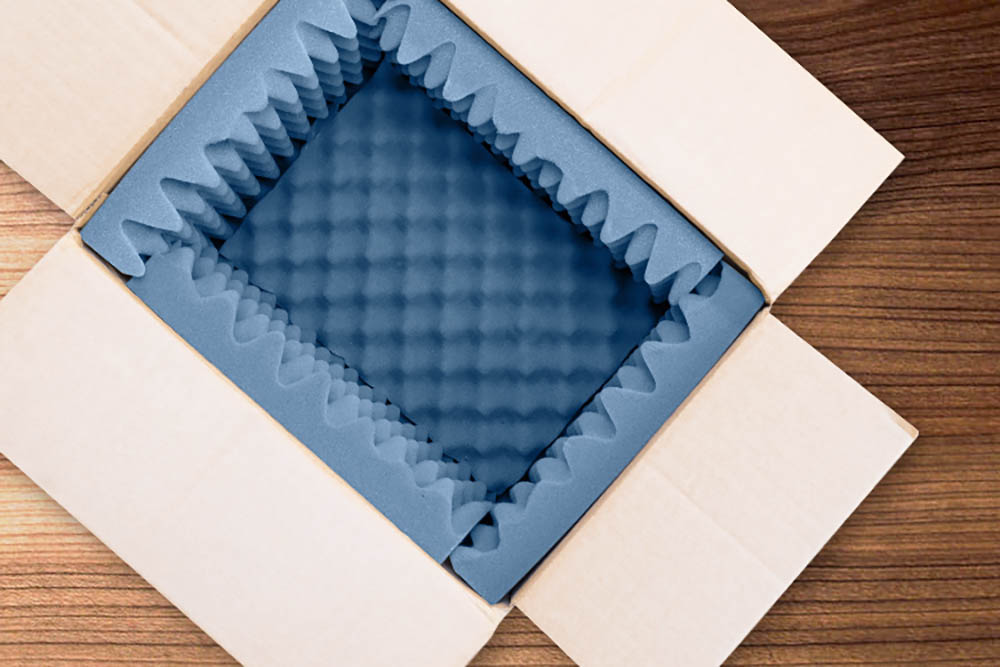

Rapid-assembly RETT-style cartons combined with convoluted (egg-crate) foam sets for flexible cushioning and universal fit. These kits are widely used for replacement parts, repair depots, spare part shipments, and field service applications where speed and versatility are essential.

Corrugated or chipboard partitions paired with custom-sized boxes for secure, separated packaging of bottles, small containers, fragile industrial parts, or multi-component hardware assortments. Designed to prevent collision, abrasion, and breakage during shipment.

Heavy-duty wood crates or triple-wall master packs combined with engineered foam interiors for export, heavy machinery, and MIL-SPEC applications. ISPM-15 heat-treated options are available for international compliance and safe global transit of oversized or sensitive products.

Complete packaging systems designed for consistent, high-speed pack-out on manufacturing floors. Each kit integrates the correct box with foam, partitions, trays, or dividers to standardize workflow, reduce labor, and support high-volume, multi-SKU environments.

Every kit is engineered to protect products from shock, vibration, abrasion, and movement throughout handling and shipment.

Systems are created to standardize workflow, accelerate assembly, and reduce labor time across production lines.

Boxes, foam, dividers, and hardware are matched exactly to product geometry to eliminate guesswork and achieve repeatable pack-out quality.

We combine corrugated, foam, wood, plastics, partitions, and hardware into single, complete kits designed for operational efficiency.

Every packaging kit maintains predictable performance across large-scale manufacturing, distribution, and field service operations.

OEM Materials engineers complete packaging systems that simplify pack-out, eliminate damage, and create consistency across your workflow. Each kit is built to match your product’s geometry, shipping conditions, fragility, and handling requirements. By combining the right container with the correct foam, partition, or cushioning system, we reduce labor, prevent errors, and support repeatable pack-out across large-scale manufacturing environments.

Whether you need packaging for medical devices, aerospace components, electronics, industrial parts, or field service equipment, our custom kits are engineered to meet the exact performance required.

Engineered kits for sensitive, mission-critical assemblies and export-compliant shipping programs.

Clean, consistent packaging systems for sterile and regulated components, kits, and devices.

Custom insert kits and foam-lined boxes that protect sensitive electronics and static-sensitive components.

Repeatable packaging solutions for staging, WIP protection, subassemblies, and multi-component workflows.

Durable kits designed to withstand vibration, weight, and rugged handling through production and shipment.

Retail-ready packaging solutions with premium presentation and protective interiors for high-end goods.

Flexible, scalable kit systems for fast-changing SKUs, varied dimensions, and rapid-turn production cycles.

OEM Materials is ready to design, source, and integrate engineered packaging kits that reduce labor, improve protection, and standardize your production workflow.

We supply custom made packaging kits to manufacturers and distributors across the United States.

Locations in CA, IL, PA, TX, and GA support fast replenishment and shorter lead times.

We coordinate shipments, manage replenishment, and support VMI/JIT programs for multi-facility operations.

Facilities near our distribution centers benefit from rapid fulfillment ideal for high-speed production.

Crate and foam kits built for global transport, long-distance freight, and sensitive international shipments.

From foam-lined kits to custom crate systems, OEM Materials delivers engineered protection your operation depends on.

OEM Materials offers complete packaging kit systems instead of loose, separate components. We build foam-lined box kits, die-cut foam insert kits, RETT and convoluted foam kits, box and divider kits, crate and foam kits, and production kitting assemblies. Each kit is designed around your product and workflow so your team can pack faster, protect better, and ship with confidence.

You do not have to guess. Our team reviews your product size, weight, fragility, and how it moves through your facility and shipping network. We look at handling, vibration, stacking, and presentation needs. Then we recommend the right box style, foam type, dividers, and crate options so your kit is simple to use, easy to train on, and provides the right level of protection.

Yes. We specialize in custom foam interiors that match your product exactly. Using CNC routing, die-cutting, waterjet, or laser cutting, we shape the foam to hold every part in the correct position. This prevents movement, limits damage, and makes pack-out repeatable from shift to shift. The inserts can be used in both corrugated shippers and reusable containers.

Yes. We design kits specifically for electronics and static-sensitive parts. We can use anti-static or ESD foam combined with the right carton or crate so parts stay protected from both impact and electrostatic discharge. These kits work well for PCBs, semiconductor components, instruments, and assemblies that must arrive damage-free and ready for production or test.

Absolutely. Many customers use our kits in closed-loop or long-term programs. We can pair reusable totes, racks, or crates with durable foam like EPE, EPP, PE, or XLPE that keeps its shape through repeated cycles. This approach helps lower total cost over time, cuts waste, and supports consistent handling across automotive, aerospace, and high-mix manufacturing operations.

Yes. We often combine corrugated boxes, wood crates, partitions, foam, plastics, and hardware in one complete kit. Our goal is to deliver a ready-to-use system that arrives to your line as a single solution, not a pile of unrelated packaging parts. This reduces setup time, simplifies training, and makes it easier for your team to follow a standard pack-out method.

Yes. We support medical and life sciences customers with packaging kits that work in clean, controlled settings. We select appropriate foams, liners, and containers to help limit particulates and support your regulatory needs. These kits can be designed for diagnostic devices, surgical tools, disposable sets, and other sensitive products that require clean handling.

Our crate and foam kits are built for demanding conditions. We can provide heavy-duty wood or triple-wall crates with engineered foam interiors that handle stacking, long-distance transport, and rough handling. ISPM-15 heat-treated options support export shipments. We select foam densities and crate designs that match your weight, route, and risk profile for each program.

Yes. We strongly encourage prototyping and testing before a full rollout. We can supply sample kits so you can check fit, run trial pack-outs, and perform drop or vibration tests if needed. Based on your feedback, we adjust foam shapes, carton sizes, or materials. This process helps you launch with a proven design instead of discovering issues during live shipments.

Lead time depends on design complexity and quantities, but we work to move quickly. Once the design is approved, we leverage our regional locations in CA, IL, PA, TX, and GA to shorten transit times. Standard and repeat programs can be stocked or supported with VMI or JIT, so your lines have packaging when needed and you avoid rush orders and stockouts.