OEM Materials provides industrial-grade flexible packaging and poly bag solutions for manufacturing, distribution, cleanroom, and export applications. From simple poly bags to high-performance static shielding and moisture barrier structures, our film and bag products are designed to protect your parts, streamline packing, and support demanding production environments.

Below is a comprehensive list of our flexible packaging products, each engineered to support industrial, ESD-safe, and corrosion-sensitive applications across shipping, storage, and production.

Poly bags for everything from small parts to large assemblies are available in custom sizes, thicknesses, and printing. We match gauge and style to your product, whether you need light dust covers, heavy-duty parts bags, or branded packaging that carries your logo and handling instructions directly on the bag.

Anti-static poly bags designed to handle and ship static-sensitive parts without building harmful charge. These bags dissipate static while protecting against dust and handling damage, ideal for electronics, PC boards, hardware kits, and assemblies moving through ESD-safe areas. Available in flat, gusseted, and zip-top formats in multiple gauges and custom sizes.

Static shielding bags engineered to protect sensitive electronics and circuit boards from electrostatic discharge. Available in open-top, zip-top, and custom sizes, these bags create a Faraday cage around your product while still allowing visual identification through the metallic, transparent film. Ideal for PCB assemblies, components, and ESD-controlled environments.

High-performance moisture barrier bags that keep humidity out and protect sensitive products during long-term storage or international shipment. Built for electronics, aerospace components, and corrosion-prone metals, these multilayer structures are designed to be used with desiccant packs and humidity indicators for complete barrier protection.

Roll stock poly sheeting for liners, covers, and general industrial protection. Use it to line cartons, bins, and Gaylords or to cover machinery, pallets, and work areas. Available in clear or tinted films, multiple gauges, and custom widths so you can dial in the exact coverage, strength, and clarity your process requires.

Shrink films for retail packaging, bundling, and tamper-evident wraps. Available in polyolefin and PVC options for both manual and automated equipment. Ideal for multi-packs, point-of-sale packaging, and unitizing small products into clean, tight, shelf-ready bundles that still showcase what’s inside.

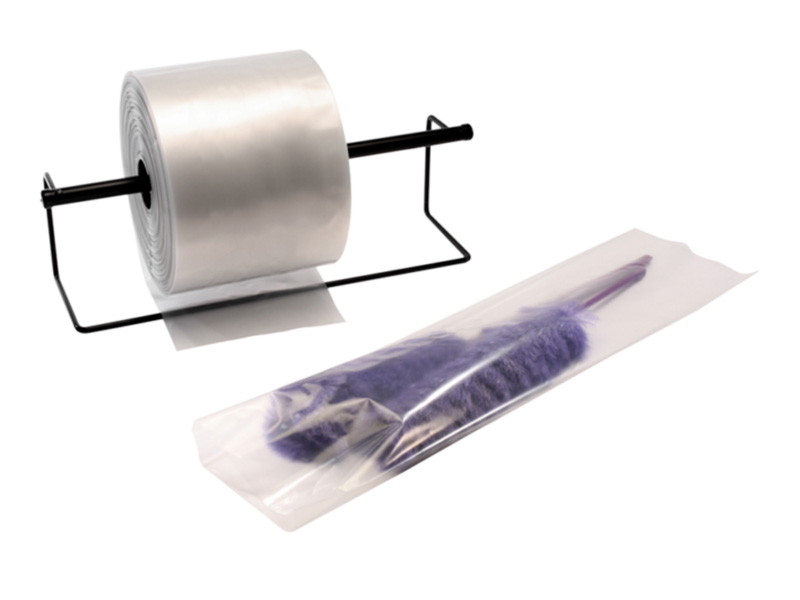

Continuous poly tubing on rolls that lets you create custom-length bags right at the packing bench. Simply cut to size, load your product, and seal one or both ends. Ideal for long or irregular items, changing product lengths, and operations that need bag flexibility without stocking dozens of individual SKUs.

VCI (Vapor Corrosion Inhibitor) poly packaging that protects metal parts from rust and corrosion during storage and shipment. Available as sheeting, bags, or tubing, VCI poly surrounds your parts with a corrosion-inhibiting atmosphere inside the closed package, making it perfect for machined components, fasteners, tools, and metal assemblies headed to stock, export, or long-term storage.

Tabletop impulse sealers for quickly sealing poly bags and tubing at the packing station. Load the bag, tap the bar, and get a clean, strong heat seal in seconds—no warm-up time and minimal operator training. Ideal for creating custom-length bags from tubing or closing open-top bags for parts, kits, and moisture-sensitive products.

Our flexible packaging lineup is designed to handle real manufacturing conditions, from dusty production floors to ESD-safe electronics lines and export warehouses.

We match bag sizes, gauges, and film types to your exact products, storage conditions, and workflows, reducing waste and improving packing efficiency.

Anti-static, static shielding, moisture barrier, and VCI structures help protect sensitive electronics and metals from hidden failure modes.

Custom printing allows you to add logos, instructions, barcodes, and compliance information directly on the bag or film, improving traceability and presentation.

Our bags and films are manufactured for uniform thickness, seal strength, and barrier properties, ensuring predictable performance across every batch and packing line.

Flexible packaging and poly bags are essential tools for protecting products, organizing components, and supporting efficient production. At OEM Materials, we engineer and source film-based solutions that go beyond basic bags, each product is selected to match specific risks such as static, humidity, contamination, and corrosion.

From standard poly bags and sheeting to advanced static shielding and VCI structures, our flexible packaging solutions are designed to integrate with your packing stations, cleanrooms, storage areas, and export workflows. Whether you are wrapping loose hardware, sealing moisture-sensitive electronics, or protecting metal parts in long-term storage, we help you choose film types that reduce damage, improve reliability, and support your quality standards.

Barrier, moisture, and VCI packaging for precision components, assemblies, and export shipments requiring corrosion and contamination control.

Clean, consistent bags and films for sterile packaging systems, kits, and sensitive devices that demand traceable, repeatable quality.

Anti-static, static shielding, and moisture barrier films designed for ESD environments, PCB handling, and long-term component storage.

Poly bags, tubing, and sheeting used for kitting, work-in-process protection, and organizing assemblies across high-mix production lines.

VCI poly and heavy-gauge film that guard machined parts, fasteners, and metal assemblies from rust, impact, and environmental damage.

Shrink films and printed bags for shelf-ready packaging, multi-packs, and ecommerce presentations that protect while showcasing products.

OEM Materials is here to help you design, source, and integrate flexible packaging that protects your products, simplifies packing, and improves production efficiency.

We supply poly bags, films, and flexible packaging solutions to manufacturers, distributors, and fulfillment centers across the United States.

With distribution centers in California, Illinois, Pennsylvania, Texas, and Georgia, we provide shorter lead times and reliable replenishment.

We coordinate deliveries and stocking programs for companies with multiple plants, warehouses, or contract manufacturing sites.

Facilities near our distribution centers benefit from accelerated shipments, reduced downtime, and quick access to replenishment materials.

Moisture barrier, VCI, and specialty films help protect sensitive products throughout long-distance and international logistics.

We offer standard poly bags, anti-static bags, static shielding bags, moisture barrier bags, poly sheeting, shrink films, poly tubing, VCI bags and sheeting, and tabletop impulse sealers. Each product is selected to support specific needs such as dust protection, ESD control, corrosion prevention, or retail-ready presentation.

We review your product weight, edges, surface sensitivity, storage time, and handling environment to recommend the right gauge and film structure. Light dust covers may use thinner gauges, while heavy or sharp parts require thicker or more durable films. For electronics or metals, we factor in static and moisture risks as well.

Anti-static bags are designed to dissipate static charge and prevent static buildup on the bag surface, making it suitable for many ESD-safe handling applications. Static shielding bags go further by creating a Faraday cage around the contents, protecting highly sensitive electronics from electrostatic discharge events. We help match the bag type to your risk level.

Moisture barrier bags are recommended for electronics, aerospace components, and corrosion-prone metals that may sit in storage or travel through humid environments. Used with desiccants and humidity indicators, they keep moisture out of the package and help prevent oxidation, PCB failures, and corrosion during long-term storage or export.

VCI (Vapor Corrosion Inhibitor) poly releases corrosion-inhibiting molecules inside the sealed package. These molecules bond to the surface of metal parts and help prevent rust and oxidation without messy oils or greases. VCI is ideal for machined components, tools, and metal assemblies destined for storage, export, or long transit.

Yes. We can add logos, handling instructions, barcodes, warnings, and other information directly on the bag or film. Custom printing improves branding, compliance, and identification and can be applied to many poly bag, tubing, and film structures depending on your application.

Poly tubing lets you cut custom-length bags on demand at the packing bench. Instead of stocking multiple fixed-size bags, you keep one or a few tubing widths and seal to the length you need. This reduces inventory complexity, improves flexibility for varying product sizes, and is ideal for long or awkward items.

Many of our films and bags can be specified for clean, low-particulate applications and ESD-safe environments. For medical, life sciences, or semiconductor use, we help you select materials and formats that align with cleanliness requirements, documentation needs, and handling standards.

Yes. We offer tabletop impulse sealers that create strong, consistent seals on poly bags and tubing. These units require minimal training, no warm-up time, and are ideal for pack stations creating custom-length bags or sealing moisture and corrosion-sensitive products.

Lead times depend on product type and customization, but our regional distribution centers in CA, IL, PA, TX, and GA allow us to ship standard items quickly and support ongoing programs with reliable replenishment. For recurring usage, we can support VMI or JIT-style programs to prevent stockouts and keep your lines running.