OEM Materials provides professional Custom Packaging Design services built for manufacturers, distributors, and product teams that need packaging engineered for performance, efficiency, and protection. Our designers reverse-engineer existing packaging or develop new solutions from drawings, CAD files, or sample parts. From custom corrugated boxes to engineered foam inserts, we create packaging tailored to your product’s exact shape, weight, and handling requirements.

Custom Packaging Design is the process of developing packaging solutions that are engineered specifically for your product, not pulled from generic stock. Our team measures your part, analyzes shipping and handling conditions, evaluates material options, and designs a complete packaging system that protects your product from production to delivery.

Custom packaging eliminates wasted space, reduces material costs, improves dimensional accuracy, and ensures better protection for fragile, high-value, or irregularly shaped items.

Below is a detailed overview of our custom packaging design capabilities, built to support high-volume manufacturing, specialized components, and sensitive or oversized products.

We disassemble your current packaging, analyze its materials, construction, and weak points, and rebuild a stronger, smarter, and more cost-effective solution. Reverse engineering helps reduce waste, improve protection, eliminate over-packaging, and streamline packing time.

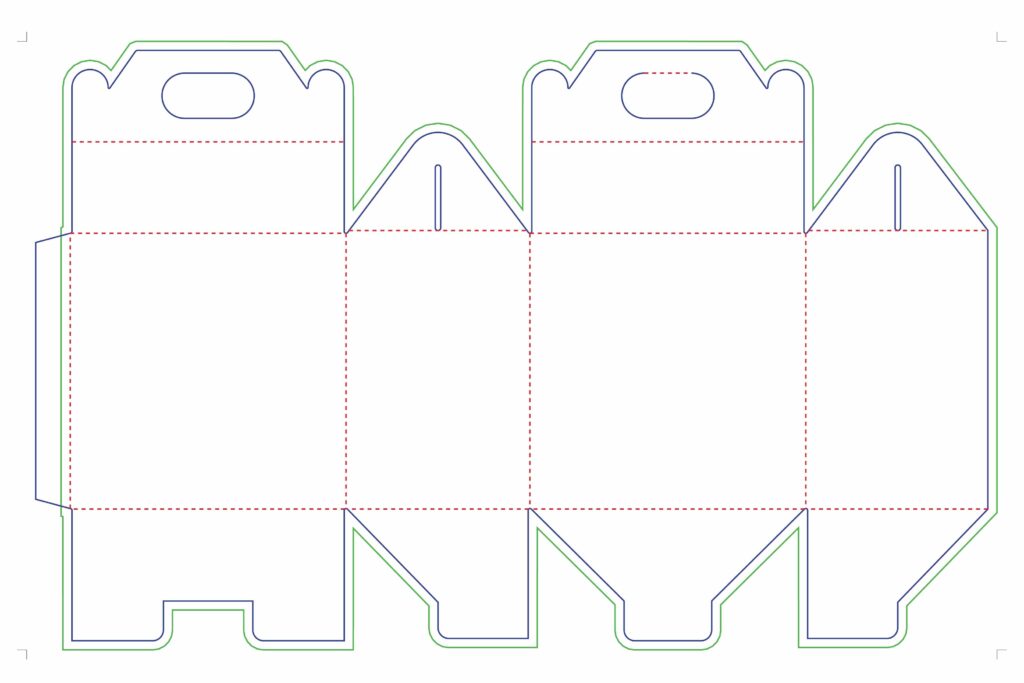

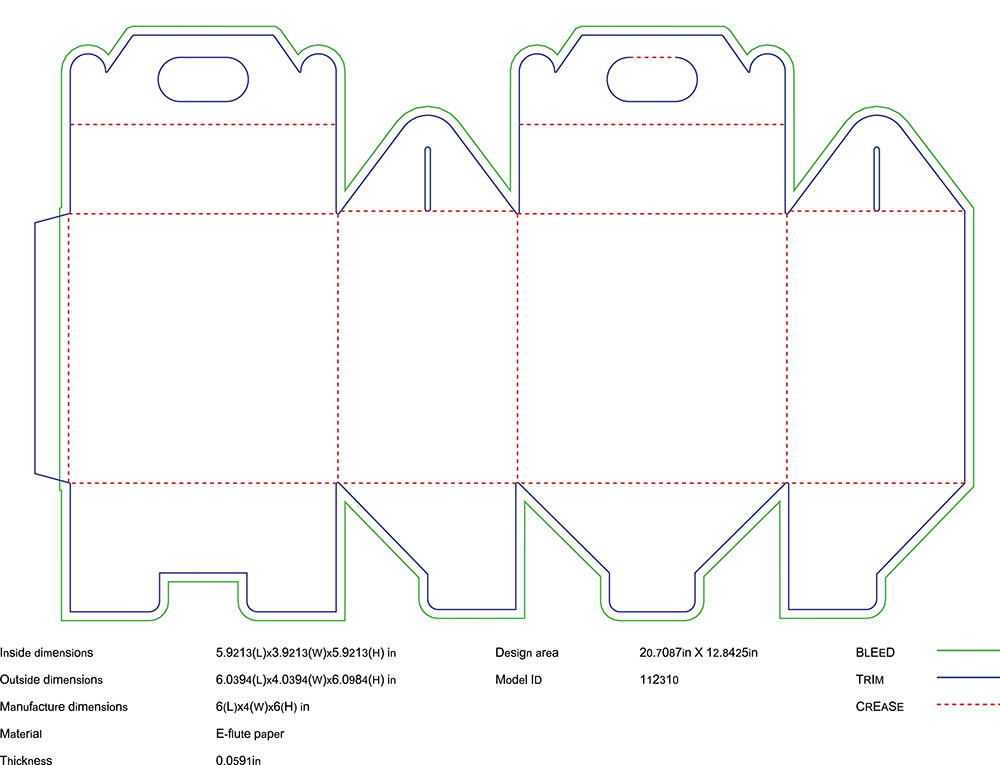

Our design team creates precise CAD drawings and provides free prototype samples for fit and performance testing. You can review, test, and refine the packaging before production begins, ensuring confidence and accuracy at every step.

We design foam systems, including PE, PU, EPE, XLPE, and anti-static options, shaped to secure your product during shipping, handling, and storage. Foam inserts are engineered based on weight, fragility, handling conditions, and drop-test performance requirements.

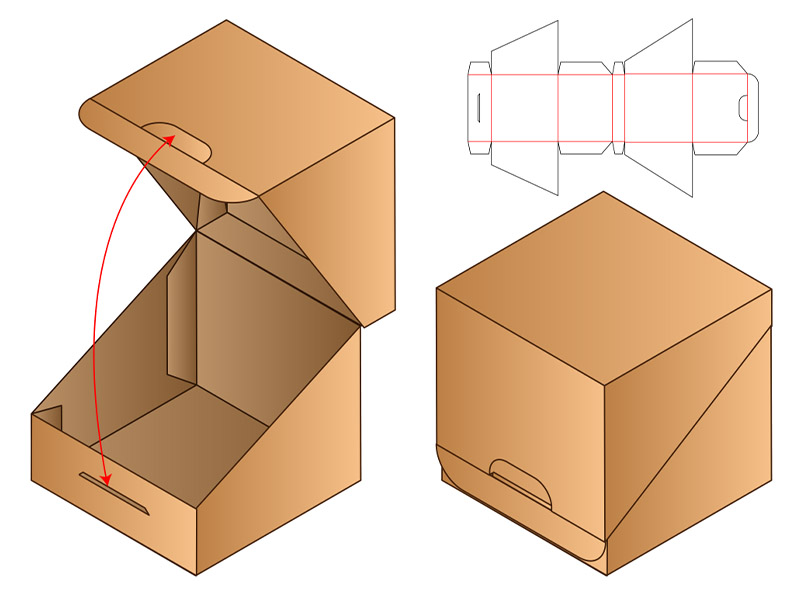

OEM Materials designs custom corrugated boxes, die cuts, and multi-layer structures tailored to your product’s measurements and shipping environment. This ensures optimal stacking strength, dimensional efficiency, and cost control.

Whether you provide digital files, physical samples, or complex assemblies, we design packaging that fits your exact specifications. Every detail—including tolerances, constraints, and handling needs—is factored into the design.

Our team evaluates a range of materials and formats, recommending solutions that cut unnecessary weight, reduce dimensional freight charges, and minimize material waste, without compromising protection.

Every packaging solution is engineered to reduce damage, prevent shifting, and protect sensitive or irregular components through shipping and handling.

Custom sizing reduces dimensional weight, minimizes wasted space, and cuts cost across your entire supply chain.

Packaging designed for your product reduces packing time, eliminates confusion, and improves consistency across your operation.

We provide free CAD drawings and prototype samples so you can test and verify performance without risk.

Our solutions are engineered with consistency in mind, ensuring every shipment stays protected and every box fits perfectly.

OEM Materials supports a wide range of industries where product protection, dimensional precision, and reliable handling are essential.

Custom foam and corrugated solutions for fragile components, assemblies, and export-regulated items.

Precision packaging for sterile, delicate, and high-value equipment.

Anti-static and shock-absorbing packaging for sensitive electronic assemblies.

Custom boxes, foam, and full packaging systems engineered for build-to-order and high-mix product lines.

Durable, impact-resistant packaging for heavy components and high-volume manufacturing.

Custom packaging that reduces damage, improves unboxing, and minimizes dimensional freight charges.

Custom packaging designed for temperature-sensitive goods, fragile bottles, and high-volume shipments.

OEM Materials supports facilities across the United States with design, prototyping, and full-scale production.

We design and deliver custom packaging solutions nationwide for companies of all sizes.

With manufacturing partners and production facilities across the U.S., we produce and ship packaging quickly and reliably.

We manage packaging design and production for organizations with multiple product lines, locations, or distribution centers.

Regional customers benefit from rapid production cycles, quick sample delivery, and responsive support.

With OEM Materials designing your packaging, you reduce damage, improve efficiency, and gain a solution engineered specifically for your product.

Custom Packaging Design is the process of creating packaging built specifically for your product instead of relying on stock boxes or generic foam. We measure your item, review CAD drawings or sample parts, analyze weight and fragility, and design packaging engineered for protection, efficiency, and cost control. You receive CAD drawings, prototype samples, and revisions until everything fits and performs exactly as needed.

We can design packaging for almost any product, including fragile electronics, medical devices, aerospace components, automotive parts, industrial equipment, consumer goods, and irregular or oversized items. If it has a shape, weight, or handling requirement, we can engineer a corrugated box, foam insert, or full packaging system that protects it. Our team works with small components up to large assemblies and multi-part kits.

The design process typically begins with a drawing, CAD file, or a sample product so we can measure and understand the exact dimensions and protective needs. We review how the item is handled, packed, and shipped. Then our designers create CAD concepts and produce prototype samples for testing. From there, you review fit, performance, and ease of packing, and we make revisions until the design is ready for production.

Yes. OEM Materials provides free prototype samples so you can confirm fit, protective performance, and ease of use before moving into production. These samples allow your team to pack real units, run drop tests, verify compression strength, and review handling requirements. Free samples give you confidence in the design and reduce the risk of damage, delays, or expensive rework once full production begins.

Absolutely. We can analyze your existing packaging, break it down, inspect materials and structure, and redesign it for better protection or lower cost. Reverse engineering helps eliminate unnecessary materials, reduce dimensional weight, improve foam placement, and solve recurring damage issues. Many customers come to us with packaging that “sort of works,” and we rebuild it into something stronger, lighter, and more efficient.

We design with a wide range of materials including corrugated board, die-cut inserts, polyethylene foam, polyurethane foam, cross-linked foam, EPE foam, anti-static foam, molded components, and specialty protective materials. Our team chooses materials based on your product’s weight, fragility, shipping method, environmental exposure, and cost targets. We always aim for the best combination of protection and efficiency.

Design timelines vary depending on complexity, but most projects begin with CAD drawings and prototypes in a short time frame. Simple corrugated designs can be produced quickly, while complex foam or multi-component kits take longer. We prioritize fast turnaround so your project doesn’t stall. Once the design is approved, production lead times depend on quantity and material requirements, but we always communicate timelines clearly.

Custom-designed packaging removes unnecessary space, lowers dimensional weight, and optimizes carton size. This directly reduces freight costs, especially with carriers that charge by volume. By engineering the exact fit, we also help you use less foam, reduce material waste, and stack more efficiently on pallets. Over time, many customers see significant savings simply by eliminating oversized or inefficient packaging formats.

Yes. OEM Materials specializes in protecting sensitive, high-value, and fragile items. We analyze drop requirements, vibration exposure, shock resistance, and handling risks to build foam inserts or protective systems tailored to each item. For electronics, we can incorporate anti-static materials. For medical and aerospace parts, we design packaging with precise tolerances and repeatable protection to prevent damage during transit.

Yes. We can design packaging for single items, full product lines, or large multi-SKU programs. Many companies come to us when they have multiple versions of a part and need packaging that fits each variation. We can also create modular foam or adjustable designs that reduce the number of packaging types you need. Our team also supports multi-facility rollouts to keep everything standardized across locations.

We use measurements, material testing, compression strength data, and protective engineering principles to build packaging that withstands real-world conditions. Our prototypes allow you to run internal drop tests and verify performance before producing anything in bulk. We refine designs based on feedback and ensure the final packaging meets your shipping, handling, and operational requirements, giving you predictable, repeatable protection.

To start, we typically need product dimensions, weight, drawings or CAD files, and ideally a sample part for physical measurement. Details about how the item ships, typical handling risks, pallet configuration, and any damage concerns are also helpful. With this information, we design a solution tailored to your exact needs. Our goal is to make the process simple while ensuring the final packaging fits and performs perfectly.